A daughter’s dairy allergies swayed a Canterbury farming couple to invest in milking sheep. Anne Lee reports.

The dairy sheep sector is gaining momentum in Canterbury with an ultra high temperature (UHT) milk processing plant being installed at Kirwee, near Christchurch, and a powder drier planned for completion by early 2024.

Sheep Milk New Zealand is a company set up by Matt and Tracey Jones and they’re keen to see a lot more farmers join them in a venture they say has masses of potential and could solve a few issues for their dairy farming cousins.

Matt worked within the dairy sector in Canterbury for several years, setting up agricultural training and staffing businesses.

He thinks there are synergies for the dairy and sheep milking sectors with opportunities for dairy farmers wanting to lower their environmental footprint or diversify their businesses.

Six Canterbury sheep milking farms are already supplying the company with milk that’s used to make traditional dairy products such as cheeses and drinking milk which sells for $4.95 per 450ml bottle. The dairy food products are sold under the Jones Family Farm brand.

Skin care products are also produced from the milk and sold under the Sabelle brand.

Farmers supplying the company must commit to a minimum pick up of 600 litres a day (300-600 sheep at 1-2litres/ sheep) with the company’s tanker doing the rounds to pick up the milk and deliver it to Kirwee.

The powder spray drier will be set up in Ashburton and will be of a similar size to the drier at Food Innovation Network’s site at Waikato, capable of processing 440kg of milk powder an hour.

Matt says it will open the way for infant formula production and allow sheep milk to become a high-quality, premium ingredient in a range of products.

It will also be available to others on a toll processing basis and Matt says there’s interest from other milk sectors including specialist bovine milks.

The UHT plant at Kirwee will allow a range of milk products to be produced

with a longer shelf life which will make exporting products possible.

Matt and Tracey have been quietly developing their sheep milking venture for about 10 years.

Their interest was sparked by a need to find dairy alternatives for their daughter and along the way they found sheep milk was better for others in the family too – gentler on the gut and helped with skin irritation.

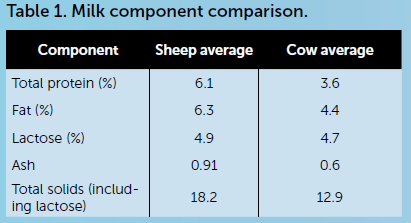

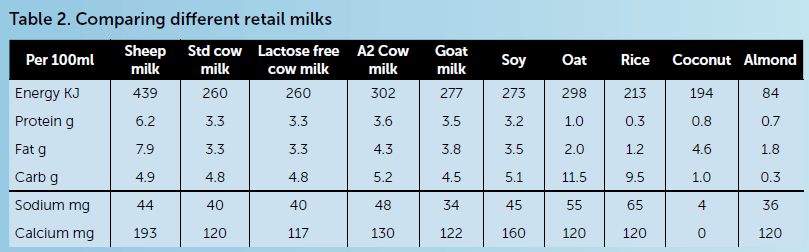

The milk is A2, high in fat, readily digested and naturally more homogenised.

In 2011 they bought part of an East Friesian stud and in 2019, buoyed by growing interest in sheep milk products from others, began commercially milking their flock.

They’re now milking 600 ewes on their 48-hectare home block at Kirwee through a 12-a-side herringbone dairy.

The East Friesian has been bred for its milking ability and widely used for generations but they can struggle in NZ conditions.

Matt says they are bringing in other breeds with the aim of creating an animal that is highly suited to the South Island environment, particularly with feet problems.

“They need to be able to handle -10C right through to temperatures that can approach 40C here in Canterbury.”

Matt and Tracey have been crossing the East Friesians with Manech tête rousse – a hardy breed from the Pyrenees and French Basque country and have also been using the Laucane which has good udder and teat conformation.

The East Friesian and Laucane aren’t known for their strong feet but the inclusion of the hardy Manech tête rousse genetics should improve that.

The sheep are run through a foot bath on the way out of the dairy and into the covered feeding area to help manage foot issues such as footrot.

Lambs stay with their mothers for four days and are then removed to a purpose-built rearing shed where they’re trained on to automatic lamb milk feeders.

They’re fed ad lib milk on the automatic feeders along with lamb muesli and silage and are weaned at 15kg at about four weeks.

They’re lambing in spring and autumn to help maintain a flow of milk throughout the year.

Ewes are on a relatively high input diet and are fed 2kg drymatter (DM)/ewe/day) of a mixed ration of lucerne silage, maize, peas, grains and other nutrients including fish oils.

It’s mixed in a silage wagon and fed on to a conveyor belt that runs at sheep dining-height into the middle of the covered feeding shed. Once the first lot of feed reaches the end of the conveyor belt in the middle of the shed, it’s shut off allowing the ewes good access to a fresh “table” of high energy milking feed.

They get an estimated 2kg DM/ewe/day of fresh pasture while out grazing but have access to the feeding shed so they can get out of the heat of the day or shelter from colder weather.

They also get 1kg DM/ewe/day of grain in the dairy with partitioned feed bins filled and then lowered to sheep feeding height as each new row comes in to be milked.

Each animal has an electronic identification (EID) tag and the herringbone dairy is set up with EID readers and milk meters so each ewe’s production is monitored.

“That’s been key to our breeding programme because we’ve been able to identify the ewes that are our highest producers,” Matt says.

Elite animals in Europe can produce up to 180kg MS/ewe or 1000 litres in a lactation.

A survey of 16 NZ sheep farmers carried out two years ago found ewes were averaging 220l each, he says.

“So, there’s a lot of potential for the industry here,” he says.

Their animals are averaging 80kg MS/ewe or 400l/ewe over 280 days.

Better producers in the flock milk 4l/day.

Matt says they’ve done a lot of learning through experience and have set up pretty comprehensive support systems for farmers wanting to become suppliers.

They have a handbook on sheep milking with best practice guidelines, kitset sheds and systems, costings and financial analysis carried out by the Agribusiness Group as well as connections and networks where advice is shared between farmers.

They’ve set up a flock testing programme to help with breed development and there are a range of educational training events.

As a rough estimate returns from milk could be up to $9300/ha.

That’s based on:-

- 65kg MS/ewe or 350l

- Average stocking rate of 12 stock units (SU)/ha (1 sheep = 1.3-1.5SU)

Costs include typical farm costs of feed, labour and fertiliser with the additional cost of shearing.

Farmer suppliers have a supply agreement just as they would have for a dairy farm supplying a processor.

It includes their responsibilities and minimum standards.

Farms are audited and have shed inspections in the same way dairy farms do.

If farmers are producing their own products for sale such as cheese or fresh milk they are required to have a risk management plan (RMP) but farms supplying a processor such as Sheep Milk NZ can operate under the company’s RMP.

Effluent from the farm dairy and other areas has to be collected and managed in the same way as dairy cow effluent, although there’s a lot less of it.

A sheep urine patch has significantly less volume and a lower nitrogen content than that of a dairy cow and that’s piqued the interest of a number of dairy farmers, Matt says.

A sheep, though, isn’t a cow and the idea of rounding up a mob of sheep twice a day may seem daunting especially for those more used to a slower-paced cow.

“They know the drill and they’re actually not flighty like a hill country sheep. They’ve been bred for this over hundreds of years and they’re keen to get in for milking each day,” Matt says.

A specialised sheep milking course is being run for the second year through Matt and Tracey’s business Agri Training company, which runs a wide range of NZQA certified programmes.

Matt says “students” in the sheep milking course are aged from 18-50-year-olds with varying levels of experience in farming.

There are a lot of synergies between sheep milking and traditional dairy farming and a lot of potential benefits for existing dairy farmers, Matt says.

“We’re definitely keen to see them join us.”