Tim McVeagh

Automation of livestock feeding, while requiring considerable capital investment, should need less labour and be a more efficient and more productive means of getting tucker down the throats of animals. But does automatic feeding stack up for calves? They can be fickle with slow drinkers and crookies.

Rearing young calves requires patience and empathy – attributes that women are often regarded as having more of than men but that machines are not renowned for.

If automatic calf feeding is a goer, what does a good system consist of? What will it do, and how well? And what’s available to dairy farmers and calf rearers?

Automatic calf feeders range from the basic to quite complex systems. The basic models provide mixed calf milk replacer (CMR) or milk on an ad-lib basis to a pen full of calves.

The most sophisticated systems have individual calf feed mix and ration programs, and monitor feeding and weight gain. And of course cost varies significantly, even between installations of the same system under different conditions.

WHY AUTOMATIC CALF FEEDING?

A successful automated calf feeder will:

Save on labour by freeing up staff at a busy time and possibly avoid the need to employ casual staff.

Rear a more even line of better, quieter calves; and quicker. These are claims made by advocates including users, though may draw on comparisons with a manual system that was inefficient and problematic. Better means heavier and healthier; quieter because there is less bullying and speed drinking; and “quicker” means reaching weaning weights earlier. The key to this is that an allocated ration of milk is fed little and often so every calf has the chance to get its daily allocation. The quick drinkers do not get more than their fair share at the expense of the slow ones. It also reduces scouring.

Provide a safer and easier workplace with less heavy lifting, hot water handling, and vehicles.

Allow ration size, blend recipe, and feeding frequency to be programmed and changed with age, even on an individual calf basis.

And it can also monitor consumption, drinking rate, liveweight, and absenteeism with alerts to any problems, which often go undetected in a manual system until calves are really sick.

David Reid of Reid Systems said that the company had two calf sheds connected by WiFi to one controller.

“Fifteen single feeders in one shed, six in the other, with approximately 35 calves per feeder. Some pens had three feeders in them. The second shed had a viewing computer with a 24” monitor to show the status of the calves.

“At the peak of the season they would have had around 700 calves in the sheds. They were our early single stalls, which we have redesigned and made them a double unit. Both teats have their own pump so both can feed at the same time”.

WHAT’S STOPPING YOU?

- Automatic calf feeders on the New Zealand market start at around $8500. Costs have not been documented in this article. Comparisons would be irrelevant as systems’ capabilities vary so much as do installation details. Maintenance costs include a scheduled annual check for some models.

- Machinery or power failures mean that a manual feeding system may need to be redeployed until the fault is found and fixed.

MECHANICS AND OPTIONS:

A typical automated calf feeder will consist of five parts:

- Storage: Milk and colostrum will typically be drawn from the farm calf milk and colostrum vats. CMR will be dumped into a hopper. Other liquid and powder additives may be drawn from containers in the main mixing/ dispensing unit.

- Mixing/dispensing unit. This allows the feeding regime to be programmed – feeds per day, litres per feed – on a mass, group, or individual basis. It carries out the mixing of CMR and blending with milk, colostrum, or any additives, and dispenses it. It can record individual calf feed consumption, drinking speed, absenteeism, and weight. It controls the cleaning system. Programming, and viewing calf records, may be done either at the unit and/or remotely.

- Delivery system: This is essentially tubing from the mixing/dispensing unit to the feeding stalls. While some

- systems have their feeding stalls as part of the main unit, most have remote feeding stalls allowing them to be sited in separate pens adjacent to the main unit. There are often limitations on the distance between the main unit and the feeding stalls.

- Feeding stalls: These may be single units or pairs fixed side by side. Most systems allow four stalls to be served by the mixing/dispensing unit and most allow the four stalls to feed concurrently. They may include a device like a slide to exclude access to the teat once the calf has consumed its ration. They may also incorporate forefoot scales to record live weight and alert any issues.

- Cleaning system: This may be manual, fully automatic, or partially automatic.

- The services needed for an automated system are usually single or three phase power, cold water, and drainage.

- WHAT’S ON THE NZ MARKET?

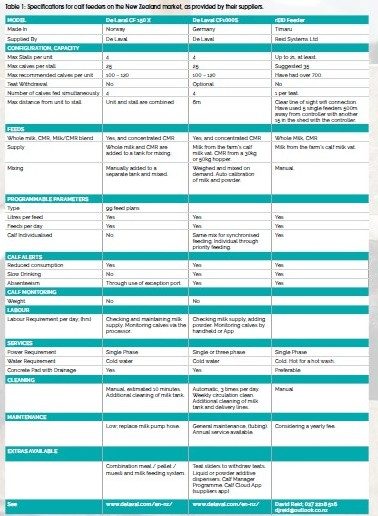

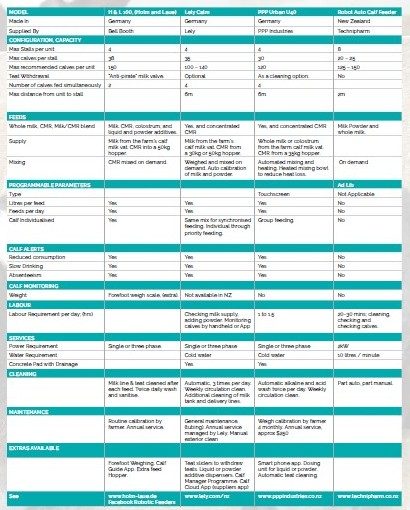

- Seven systems were found during research for this article. In addition, Calf Smart feeders made by Zeddy in Palmerston North are undergoing a review and will be back in the market at some time in the future. Details of the feeding systems currently available, as provided by their suppliers, are presented in Table 1 (p42).

- As usual, best practice for any prospective purchasers is to ask the reps to arrange for you to visit a farm during feeding. Other considerations that should be made, apart from cost, include on farm modifications needed to accommodate an automated system, technical back-up, and emphasis placed on New Zealand made.