When the payout was low, a sharemilking couple made an investment that meant they could avoid using bulls and the risks and costs they entail. Anne Lee reports.

It might seem a bit about face but Jeremy and Stacey Duckmanton’s decision to make a major investment in technology so they could get through the low payout period has turned out to be the right one, and not just for the short term.

The couple sharemilk close to 1000 cows in Mid-Canterbury, inland form Rakaia, and are equity partners in a 2300-cow lower-order sharemilking job at Kurow, two-and-a-half hours south of Rakaia.

They’re now going into their third season of a no bull, all artificial insemination (AI) mating having spent about $20,000 on a Protrack Heat camera back in 2016.

They’d been through two consecutive low-payout years and going into the 2016-17 season cashflow was still tight.

“We had a part-time person who came in Monday to Friday to do the morning milkings. He was leaving and we decided we weren’t going to replace him but we had to work out how to make that sustainable,” Jeremy says.

‘There was definitely some irony in spending money on technology in a season like that but for us we found it was the easiest way in our system to get through.’

“I’d gone back into the shed milking every morning from Monday to Friday myself, I was rearing the calves too, but I could see mating was going to cause some issues,” he says understating just how far he was already stretching himself.

“So we decided to use the chunk we saved from the wages we weren’t paying to pay for the camera,” he says.

Having already put Protrack in the farm dairy themselves a couple of years before Jeremy had spent about 12 months before the payout crash looking into the benefits of adding in the heat detection camera.

“There was definitely some irony in spending money on technology in a season like that but for us we found it was the easiest way in our system to get through and, with the big picture at the time about probably expanding into other properties, we thought it would bring consistency and allow me to be across more than one farm.”

Jeremy says that first mating though was a test of trust and he admits it took a bit of time to fully accept the camera was getting it right.

“We did a month’s pre-mating heats before mating so we spent $2500 on extra heat patches and for four weeks we basically pretended we were AI’ing.

“We’d set the camera up, draft the cows out it said to every morning, run the cows back over the platform and then we’d check the patches and make sure it was getting everything.

“It made it seem like a long mating but it was well worth it because by the time we staring mating we knew what we were doing and felt like we trusted it.”

As well as learning to trust the camera, Jeremy says he learned that in the absolute worst-case scenario he could get the cows in, milk them and get them mated singlehandedly.

“What I’ve learned is that the camera does not make a mistake – it reads what is put in front of it and it always gets that right.

“So if the cow is in the Ez Heat group on Protrack and the heat patch is missing or it’s dirty, the camera is going to tell the system to draft that cow out.”

In Jeremy and Stacey’s situation once the cow is mated a new patch isn’t put on until the following afternoon.

So a cow mated on the Monday morning won’t have a patch reapplied until Tuesday afternoon.

It took a bit of trust at first to see a cow with an activated heat patch on the Tuesday morning just walk out of yard.

“That was a tough one, it’s a horrible feeling but the camera really doesn’t make mistakes.”

Jeremy knows because initially he double checked – looking the cow up on the computer – always to find she’d been mated the morning before.

Year one taught him that it was more about managing the heat patches than trusting the camera.

“We had trouble with patches falling off and cows getting drafted out (as possibles for mating) when they shouldn’t have been.

“So in the second year we prepared them better, used more glue.

“We were more proactive with cleaning the patches – so a few times through mating, during the afternoon milking, we had someone stand up and give them a clean.

“Trimming tails – that’s become a non-negotiable because that makes a huge difference to how dirty the patches get.

Tail painting still needs to be frequent too.

“In the first season we only tail painted every 10 days or so thinking we’d rely on the heat patches but if we did lose a heat patch we couldn’t be 100% certain she was on (heat) – 10 days between tail painting meant it just wasn’t clear enough.

“So we went back to every five to seven days.”

Early pregnancy testing to save on patches

With year three coming up Jeremy is refining the system further and will pregnancy test on December 15.

That will be week eight of mating enabling him to identify cows in-calf to the first three weeks of mating.

Cows confirmed pregnant for those weeks will have their heat patches removed and they’ll be taken out of the Protrack Heat camera system so the camera won’t look at them as they come around on the platform.

“We usually get about a 50% three-week in-calf rate so we should be able to drop out about 500 cows that we won’t have to have patches on.”

Jeremy says they’ve consistently found that patches dropping off are from cows that are 35-40 days from their last mating.

“So they’re likely to be in-calf but in that last month of mating we have a lot of cows being drafted off for lost heat patches that we really don’t need to be dealing with at all.

“There might be 10-15 cows that need to be mated but we’ve got 30-40 in the yard and that’s frustrating because it takes up time.”

The season before the camera Jeremy had used AI for six weeks and bulls for four weeks followed by 11 days of short-gestation length (SGL) semen.

Going into the all AI programme they carried on with six-week AI using Premier Sires and then went to four weeks with Hereford SGL followed by 11 days of Crossbred SGL.

“What we’ve found is that 11 days of SGL at the end gets us back to a 10-week calving period even though we’re doing 11.5 weeks of mating.”

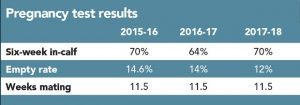

The first season’s drop in six-week in-calf rate after using the camera had Jeremy and Stacey ready to point the finger at the camera.

“I was so worried that somehow we’d missed heats and we were going to put huge pressure on the empty rate but we got more cows in-calf from week seven to the end of mating than we’ve ever done before.

“When we talked to other people and looked into it, the whole district was down about 5-6% on six-week in-calf rate.

“The fact that at last year’s mating, the six-week in-calf rate was back up to 70% really tells me that it was just a seasonal thing.

“What’s been a big positive is the drop in empty rate down to 12%.”

Costs and benefits

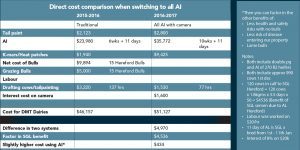

Jeremy’s analysis (figure 1) shows that cost-wise it’s pretty similar between bulls and all AI.

“We’ve done 81 days of AI instead of 42 but the extra AI cost is offset by the bull costs – the difference between what I would have bought and sold them for and the extra feed the bulls would have eaten while onfarm.

He’s saved 60 hours in labour by not having someone spotting cows.

“That’s not a lot and really for us it doesn’t mean we’re not paying those hours it’s just that people are free to do something else and we can have that long AI period and keep people’s hours at a good level.”

His team – which now includes the labour unit he took out during the tough times – averages 44 hours a week through the season.

Jeremy says he talked to staff about how they felt about the all-AI programme and they didn’t feel it was adding undue work pressure or time to their day during the period they would normally have been running bulls.

“During the weekends when there’s only two on it means they have to come back to the shed after milking when they’d normally go home but they take turns so it’s only realistically one day in the weekend.

“They’ll only have two extra weekends of AI anyway because of the roster so they don’t see it as a big deal.”

While costs are similar, Jeremy says there is an income advantage in that the ability to use SGL semen from week seven to 10 of mating gives him extra days in milk.

Based on his records he gets 120 cows in-calf to the SGL Hereford so an average extra 3.5 days at 1.8kg milksolids (MS)/cow/day and a $6/kg MS payout gives him an additional $4536.

“That’s the cream on the top really – puts me into the positive.”

But there are other advantages Jeremy and Stacey value highly too.

“I can see how mating is tracking through the whole mating period – if we realised that for some reason we were having a real shocker we could extend it.

“When we do preg testing we have a mating date with every preg test and that allows us to run the farm more efficiently.”

Minda can tell them very accurately what their expected calving dates are so they can manage autumn drying off and winter management more accurately and, through calving, get pretty detailed with springer management and their spring rotation planner for pasture allocation.

“Having no bulls to worry about with the issues around Mycoplasma bovis is a big plus too. It’s just one less thing we have to worry about with that.”

No bulls also means fewer headaches around damage to the farm and risks to people’s safety.

“That can be quite a risk – when you have people onfarm who can be new to farming. They’ve only been here for four months and then you’re asking them to go and move bulls around.”

Jeremy says he’s definitely a fan of the camera as a heat detection tool but warns that it doesn’t do the whole job on its own.

“It’s like a person picking the cows based on specific criteria and it does that job very accurately.

“But you still have to look at the cows drafted off and make decisions based on what you’re seeing.”

As long as the patch has been activated and a cow’s not there because the patch is dirty or fallen off then she’ll be put up for mating.

While he’s confident in the camera he says it’s also important to make sure everything else about the system in the farm dairy and yard is working as it should.

“The very first day of mating in our first year using the camera the compressor in our auto-drafting broke down so I had to stand there and manually draft out the cows the camera was finding.

“Apart from that we’ve had two cows in two years not get drafted out when the camera told the system to.”

Jeremy used the photos to help identify the cows and found one was a dirty heat patch anyway. The other was a real candidate for AI and the photo made it easier to find her out in the paddock.

It’s hard for a farmer to compare their own accuracy with that of the camera given they just don’t know how many heats they miss.

“It’s a big call to say you’re 100% accurate but the camera really doesn’t make mistakes.”

Farm facts

50-50 sharemilkers: Jeremy and Stacey Duckmanton

Owners: Murray and Wendy Marshall

Areas: 238ha

Cows: 970-990 Friesian cross

Production: 485-500kg MS/cow

Supplement: 1.1t DM/cow

Pasture utilised: 15.6-16.9t DM/ha/year

Sharemilking costs: $2.61/kg MS (3 season average)

Farm dairy: 80-bail rotary

Wintering: Grazed at neighbours on kale and fodder beet.