Collaring the heat

Technology, including Tag collars has helped boost in-calf rates on a mid-Canterbury dairy farm. Anne Lee reports.

Canterbury farm manager Barry Flynn doesn’t hesitate even for a split second when asked if he’d put cows up for mating based solely on the collar technology he trialled last mating.

“Absolutely – 100% I’d be prepared to let the collars make all of the decisions,” he says.

The 29-year-old Irish-born farmer first came out to New Zealand in 2015 and spent two and half years here before heading back to the home farm.

He only lasted 12 months though before he was back.

“Once I was home for a while, I just knew New Zealand was where I wanted to be – where the opportunities were.”

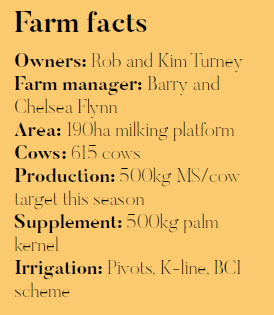

He spent a year working for Rob and Kim Turney near Methven as a 2IC on their dairy operation, adjacent to their piggery before he took up the reins as manager on the couple’s new dairy conversion not far away, near Mount Somers. The 190-hectare milking platform was sown straight out of pine trees and Barry was involved in the conversion process. It was amazing to see the transformation, he says.

The majority of the cows came from the North Island in time for the 2019/20 season.

“We’re still a work in progress – the ground was pretty hungry coming straight out of trees but it’s really benefiting from the pig effluent we can bring in from the piggery at the other farm,” he says.

It’s helping build organic matter naturally together with the breakdown of the wood material left behind in the soil.

It’s applied by Ashburton contractor Matt Lovett using a 28,000-litre slurry tanker and 18-metre dribble bar set-up that lays the pig slurry directly on to the soil rather than covering the plants.

The cows, too, have been a work in progress.

“Most of them came from a high input, system five farm and we’re still working on a number of approaches to improve mating results.”

This last mating, he worked with Tru-Test on a validation of their Tru-Test Datamars Active Tag collars and while he can’t say definitively they were the sole reason for the improvement – early scanning has shown a 4% increase in six-week in-calf rate and an 11% boost to the in-calf rate out to seven weeks.

“What I can say definitively though, is I could not fault the technology.

“We still had K-mars and tail paint so I was picking cows too as part of the validation.

“There were a handful of times when a cow was on the heat list on the app, based on what the collar was picking up, and I’d look and think ‘nah maybe she’s not on’ – you know I’d be a bit doubtful.

“But I’d draft her off and later ask the AB tech what they thought and sure enough she was on.

“It worked the other way too a few times when I thought a cow was on and she wasn’t on the list.

“I’d look up her previous heats and decide on waiting and she’d come up a few days later with a very obvious heat.”

Barry says he’d done some research and knew the technology and algorithms being used were backed by a lot of data so the accuracy should have been good – but it really met and even exceeded his expectations.

“We moved our mating earlier by a week this last mating so we’ll start calving on August 1 this year instead of the second week in August.

“We still had 62 cows to calve at the start of October last year so we knew we needed everything in our corner helping us.”

They AB’d for six weeks, ran the bull for four weeks and then AB’d for a week using short gestation length (SGL) semen.With the collars, Barry says it could now be possible to drop the bulls and mate for 10 weeks.

“They talk about mating fatigue – especially if you’ve been doing premating heats.

“By the time those last couple of weeks come you’re having 600 cows go past you and you’ve got to spot the four or five that are on.

“Collars don’t get mating fatigue.”

The collars give a level of comfort too when putting cows up that have returned.

If you can see that strong heat on the app – it’s disappointing to see she hasn’t held the pregnancy but it takes away any fear of causing a loss by inseminating unnecessarily.

The sensor tag on the collar measures:

- Standing

- Resting

- Lying

- Ruminating

- Feeding

- Group behaviour and 22 other gestures that include chin resting, sniffing and riding.

When first fitted to the cow each sensor builds an individualised picture of the cow’s behaviour for a week – setting a baseline because every cow will have its own “normal.”

Data readings are automatically uploaded to Datamars Livestock Live when the animal is within 1km and line of sight of the gateway reader set up at the farm dairy.

For Barry that applies to most of the farm, so there are only a couple of paddocks where the data, which is still continuously monitored and recorded by the tags during the time they’ve been out of sight, is being synched to the reader as the cows are coming in for milking.

“I never had a time where I was waiting for the information to download – the mating list was always there ready and fully updated by the time the cows got close to the shed even when they’ve been in the paddocks beyond the reader sight.”

Algorithms from millions of data points and machine learning have been used to inform the software that interprets the data from each cow.

It’s presented on an easy-to-read dashboard that’s available via an app on a smart phone, computer or device with clear graphics indicating rumination and heats along with screens showing other behaviours.

“You can clearly see the heats and if you look at the other behaviours, you’ll see changes that correspond with that.

“For instance, there will be a heat spike and a dot on the graph to indicate a heat and that it’s time to inseminate her but you’ll also see her rumination has gone down, her standing time is up but her time feeding has gone down.

“I get a heat report each day – so as they come into the shed I have the report with the list of cow numbers on it.”

The system can be set to automatically sync with most automatic drafting systems or the numbers could be put into the drafting system manually.

“So at the end of milking there they are – all the cows waiting, drafted out ready for the AB tech.”

The system is integrated with LIC’s MINDA adding to the ease and power of recording information.

Like so many farms Barry was short-staffed through the early part of the season.

“That’s one of the huge advantages in having this kind of system and another reason why we’re using it – it means you can have a less skilled person in the shed over mating, it doesn’t always have to be me.”

Getting cows in calf and pasture management are where the profit is in dairying, he says.

“I might be able to pick cows somewhere around the accuracy of the collars – although I think people probably overestimate their skill there.

“For me – if I can have the collars do that job – my time can then be spent making sure cows are being well-fed and we’re getting pasture management exactly right

“It’s all about quality – and getting the allocations and residuals right. I do a pasture walk every week – every five days when we’ve got rapid growth.”

Barry says it is fascinating having access to all the information in the palm of his hand. Other staff members have the app on their phones too. It creates interest and is a great tool to spark discussion and those teaching moments. The data being measured and monitored has strong correlations to animal health too.

Health reports and alerts can be sent as soon as the Tru-Test system’s analysis of the data sees negative variance in the animal’s activity compared with its “normal” state.

For instance – if rumination is down or feeding time drops an alert can be sent so the cow can be drafted out and checked over, often allowing early treatment or actions. Again it’s a tool that could also help when staff aren’t skilled in spotting issues especially over the busy periods such as calving and early spring, Barry says.

“We have 25ha of kale on the farm – 10ha we use through the autumn and the other 15ha is used in spring.

“It’s allowing us to move that calving date forward because we’ve got more feed available in those early weeks.

“Once we have 200 calved, we start using it with the spring rotation planner.

“Cows are going out to grass after milking in the morning for about four hours and then we open up the kale break.”

Cows are also fed palm kernel in the farm dairy with up to 500kg/cow used over the whole season.

“Milkers aren’t pushed at all over August and September – we bring the springers in if we need to nail the residual.

“I’ve got a great 2IC I completely trust in the shed monitoring the cows but having the health alerts is a backup for her and I can get on and manage the grass and feed allocations – it’s a big focus for me.”