Technology gives Canterbury contract milker Daniel Joho the data to make informed decisions about his farming operation. Anne Lee writes.

Daniel Joho is used to data.

Daniel Joho is used to data.

Numbers and calculations are the nuts and bolts of his previous career as a process engineer.

So, it’s no surprise he looks to technology that can give him the data to make informed decisions when it comes to his 1260-cow contract milking job at Crenlea farm near Carew in Canterbury.

Crenlea is owned by the Acland family from Mt Peel Station and covers 470 hectares with 360ha of that area used as milking platform while the remainder is used as support land including wintering.

It’s Daniel and his wife Laura’s fourth season on the farm and their seventh in Canterbury.

Having worked as a process engineer for Fonterra he and Laura headed overseas for a couple of years and then decided the time was right to come home to the 350-cow family farm at Dannevirke to give dairying a go.

The first year was great, with an $8.40/ kg milksolids (MS) payout but the second year saw the milk price almost halve to $4.40/kg MS.

“We reassessed the situation,” Daniel says wryly.

They decided to take a look in Canterbury, with the scale and opportunities for progression a drawcard.

Irrigation too was new and as it turned out they secured a job where they could learn from the best – contract milking for award-winning farmers Mark and Devon Slee.

“We were there for three seasons and yeah, I learnt so much.

“I’ve always been really open to learning. I think having a bit of experience under your belt helps too,” the holder of a Masters degree in Dairy Science and Technology says.

It was a big jump going from 350 cows to 900 and having no staff to employing three people.

At Crenlea they employ five staff and as well as having a much larger farm to run they’re also making steps on the progression ladder, taking on an equity partnership five years ago with Daniel’s parents Mike and Jane.

The 570-cow, 160ha property is at Eiffelton just north of the Rangitata River in Canterbury.

His parents are living on the farm, having sold the Dannevirke property.

Cows on both Crenlea and the Eiffelton farm have Allflex collars, both farms use the Irish-built AgriNet pasture management software and apps as well as Ravensdown’s HawkeEye to order, record and report on fertiliser use.

“Where you can, you want to be taking the guesswork out of the decisions you’re making,” Daniel says.

Having systems that are recording data for you or are simple to input information into and then having the calculations going on in the background to create alerts, reports or screens that give you relevant information can save significant amounts of time and importantly lift performance.

“We could manually do a lot of what the technology does but that all takes time.

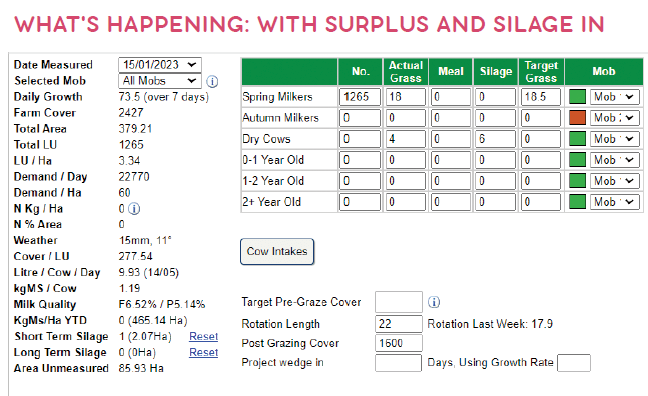

“AgriNet’s a good example of that – but once you’ve put the pasture walk data in – and I do that on my phone as I’m going around the farm – then it just takes a few clicks back at the computer and you can see where you’re at straight away.

“What I like, though, is that you can do quite a bit of what-if stuff.”

Daniel walks Crenlea every Monday with his 2IC or herd manager stepping in if need be.

“The boys plate the next 10 paddocks in the grazing round on a Thursday so we can see how we’re actually looking compared with the plan in terms of pre-graze covers,” he says.

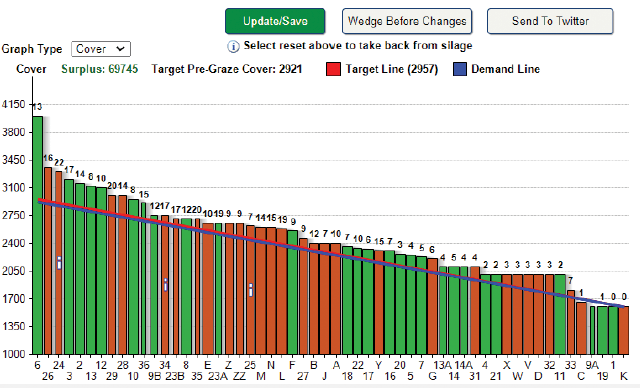

The staff can access the app and Daniel says having a visual feed wedge that, at a glance, tells an accurate story is so valuable to everyone on the team.

It’s probably the most-viewed piece of information on the farm.

“It’s user friendly so I can easily adjust the number of cows and how much grass we’re targeting for them to eat each day.

“It puts up the demand line and then we can play around with that so it fits the wedge.”

A table produced by Canterbury farm consultant Jeremy Savage – also the farm’s consultant – provides a guide for how many kg drymatter (DM) per cow are needed based on varying liveweights and the average milksolids (MS) production per cow per day they are targeting.

It assumes feed is providing 12 megajoules of metabolisable energy (MJME)/kg DM and 85% utilisation of that feed.

Daniel says AgriNet is also useful in managing surpluses.

Earlier in the season, growth rates shot up to 99kg DM/ ha/day and the wedge clearly showed a surplus with the four next highest cover paddocks well above demand.

Daniel could model taking them out for silage to see how this affected the feed situation but he could also model what the feed wedge would look like two to three weeks out if the growth rate dropped back to 65kg DM/ha/day.

“I can look at the weather forecast or where irrigation is at and think about how growth rate might track and I can play around with taking out one less paddock to see where that puts us.

“It’s not going to tell you exactly what to do and be 100% accurate on what will happen because there are variables no one has control over, but at least you can see a range of possible scenarios.

“Then it’s up to you to make a call but it’s a decision based on data not guesswork.”

Supplement is recorded in the programme too and this then adjusts the demand line which is showing demand from pasture. The aim is to use less than 500kg DM/cow of bought-in supplement to produce a targeted 580,000kg MS and AgriNet helps him manage that.

“If I look back at spring for instance, we were pretty tight in September because of the weather.

“I can see on the screen that on September 12 we had 1250 cows calved. They were getting 13kg DM/cow/day of grass, 4kg DM/cow/day of meal and 2kg DM/cow/day of silage.

“The average cover was 2160kg DM/ha and we were only growing 20kg DM/ha/day but we had a demand of 40kg DM/ha/day and we were on a 28-day round.”

“I could adjust the amount of supplement going in and see how that’s

influencing the demand line and I’m also keeping an eye on round length.”

That’s worked out by the programme and shown on the screen and manually is based on stocking rate multiplied by kg DM pasture/ cow/day you are targeting to give you demand. The pre-graze cover minus the post graze residual gives you the amount cows are eating and if that’s divided by the demand you get your round length.

For example:

- 1200 cows/340ha = 3.5cows/ha

- 5cows/ha x 18 kg DM/cow/day = 63kg DM/ha/day demand

- 2900kg DM/ha – 1500kg DM/ha = 1400kg DM/ha

- 1400kg DM/ha/63kg DM/ha/day = 22 days round length

Daniel says they use the spring rotation planner alongside AgriNet to ensure they get out to balance date – where pasture growth rates are meeting demand – which is usually October 1.

From then it’s a matter of monitoring for surpluses and maintaining a round length of 20-22 days. They aim to keep round length at 22 days right through to February and only push out to 24 days until about March 20 when fodder beet growing on the milking platform starts being fed.

“Then we push out to about 30 days but stay there quite deep into April just to make sure we don’t end up with a mountain of feed ahead of us.”

Last year Jeremy set up AgriNet so that several of his clients could see each other’s feedwedges.

“It’s a good benchmarking exercise – I can compare growth rates and round lengths and see how they’re tracking and see if we’re in the same ballpark.”

Daniel also uses the programme to help prepare feed budgets and then track actuals against budget.

“The more information we have – providing it’s in a form that’s easy to use – so programmes like AgriNet are doing the calculations in the background for you – then the better our decisions can be, especially when we can try out different what-if’s.”

Collars catch the heat

Although the jury’s not back in yet on this year’s reproductive performance with pregnancy testing not carried out yet, Daniel says the Allflex collars were definitely picking cows on heat, saving him weeks of early mornings and enabling strategic changes to the mating plan.

Last season they mated for 11 weeks but that meant Daniel getting back up on the stand after New Year to pick cows for short gestation length semen.

This season’s mating the mating length has stayed the same but the collars have done all the picking for a full AI mating period.

They used sexed semen early in mating and also mated the heifers.

“We did 12 days of mating for replacements and then went to beef until the middle of week five and then switched to short gestation length.

“I was so much fresher over mating and that’s got to mean a clearer head for the other decisions.”

The health alerts had saved a cow on the equity partnership farm with a displaced abomasum picked up and successfully dealt with by the vet.

“It will be interesting to see how the rumination and health information develops as more research is done on what good really looks like and how we can make more use of it.”