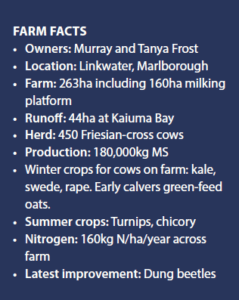

Turning around a tired, neglected farm in the Marlborough Sounds has earned Murray and Tanya Frost award recognition. By Anne Hardie.

Ten years ago Murray and Tanya Frost’s new farm on the edge of the Marlborough Sounds had no power to the paddocks, no water systems, a tiny overflowing effluent pond and was covered in browntop and rushes.

Today it is a different farm and they have won an environmental award for their efforts.

Turning around a non-compliant dairy farm won them the farming category at the Cawthron Marlborough Environmental Awards, winning praise from the judges for embracing compliance standards and going beyond requirements, while building up herd numbers and production.

They were looking for a new challenge to sink their teeth into when they bought the farm, having bought their first dairy farm on the West Coast when it was in its developing stages and flipping pakihi soils.

They found a dilapidated dairy farm at Linkwater, nudging on to the edge the Mahakipawa Arm of Pelorus Sound and flanked by steep bush-clad hills.

Mt Oliver, as it is known, only had power up one side of the laneway and the back of the farm was barbed wire and netting. Cows drank from streams or the few troughs that filled slowly from streams.

Gorse flanked the streams, while rushes covered the paddocks. A travelling irrigator didn’t make its way successfully across the paddocks because of the rushes and rough ground. The lack of stormwater diversion from the dairy to the effluent pond meant it quickly overflowed to the stream. Fonterra deemed the farm a new conversion.

The 220-cow herd on the 263 hectares was averaging 77,000kg milksolids (MS) and running a few beef cattle on rougher hill country, while scrub covered a chunk of the farm.

Murray and Tanya now milk 450 cows on a 160ha milking platform, producing about 180,000kg MS and they have a goal of reaching 200,000kg MS next season. Plus, they run 110 calves and 30 drystock on the property. The rougher hill country has been improved and they have recently cleared the remaining 20ha of scrub to develop into pasture.

Their first priority on the farm was simply adding an earth for the electric fences and getting power to all the paddocks to stop the cows wandering.

Next was adding a storm water diversion from the dairy so it didn’t enter the effluent pond. During the next two years they installed three water systems for stock, the dairy and the house. For the stock that meant buying and installing 60 troughs around the farm and putting in 5km of pipe.

As the water systems went in, they fenced off waterways and began planting with plants grown by father, Rex. Recycled vineyard posts have been used to fence waterways and there is no shortage of them in Marlborough. Numerous culverts have been added, even before regulations required them and Murray says it was simply good management practice as well as being better environmentally.

It hasn’t all been straightforward in their bid to build production.

After buying 79,500 Fonterra shares with the farm, they could only buy more as their income increased. But they could only increase income with more shares to increase production. It slowed the development of the farm, though they have still been able to make staggering change.

A third house was built for their second full-time employee, the dairy expanded from a 24-aside herringbone to 40-aside and the yard extended for a second time in 10 years to hold 500 cows.

The effluent system had a major upgrade three years ago to become a plastic-lined, 2.6 million litre pond that provides 75 days of storage. Effluent passes through a GA Slope Screen solid separator and the pond has had a stirrer added just recently.

All up, it is a $200,000 investment that more than caters for the size of the herd and can now be spread over 70ha of the farm via K-line which also irrigates from a 22m bore. From October they direct the stormwater into the pond because they have the capacity. It not only provides more irrigation for Marlborough’s typically dry summer period, but also reduces the amount of nitrogen applied to those paddocks.

This year they applied just 160kg N/ha/year across the farm and that was even after a major flood last July that held grass growth back. The scale of the effluent pond proved its worth during the flood as they still had the capacity to store effluent until September when the ground was dry enough to distribute it over paddocks.

Ongoing flood problems

The flood has been a speed bump for the farm. It brought forestry slash down across paddocks and left silt in its wake. But the biggest problem was damage to the roads. Nearly a year after the flood, the narrow winding road between Linkwater and Havelock is cluttered with lights as repairs continue. Trucks for fertiliser, stock and just about anything connected with farming need permits and a pilot vehicle to negotiate the road.

The Frosts own a 44ha runoff the other side of Havelock near Kaiuma Bay where the calves go at the beginning of July and in-calf heifers return home. It usually takes about 20 minutes to drive there and check stock, but for a couple of months they had to drive in the other direction to Picton to get there which was a 6.5-hour trip one way. Every second week the tide was right for them to take the boat from Mahau Sound to the runoff which saved them hours.

Fences were a casualty on the runoff in the flood, so half the heifers were sent to a grazier near Seddon and this winter they sent 100 cows as well.

That is aimed at reducing pasture damage, growing more grass for spring and hopefully using even less nitrogen. Part of their plan is to find another runoff so they can winter most of the herd off the milking platform and reduce the amount of crop they grow. But that second runoff has been elusive.

This winter they have 4ha of kale planted which is 5ha less than last year due to fewer cows, plus 2ha of swede and 2ha of rape which are the same as last year. Three hectares of oats have also been planted to feed early calvers in spring. Because they need winter crops to feed the cows on the farm, they buy straw to top the cows up toward the end of the season because those paddocks are out of the round.

For summer, they grow 6ha of turnips and 3ha of chicory for the dry. In the past the chicory crop has been hit hard by large numbers of Paradise ducks which prompted them to try raphno for a while. But the raphno bulb broke up too easily under cows’ hooves and it was expensive to grow so they have returned to chicory with the help of duck shooters.

Even with irrigation to 70ha and summer crops, they still switch from twice-a-day milking to 3in2 for summer, depending on the season, then once-a-day at the beginning of May to build condition on the cows. When they switch to 3in2 milking, they milk 5am and 5pm one day and then 10am the second day. As daylight saving finishes, they change that to 5am and 3pm the first day followed by 10am the second day. That way, everyone is home in daylight at the end of the day.

Regrassing and pasture have massively improved production. In the past decade they have disced and regrassed the entire farm at least once and now have their own air seeder so they can top up the paddocks with a mix of ryegrass, clover, chicory and plantain.

Pasture is benefiting from improved fertility in the soil which gets good doses of local mussel shell lime for calcium and magnesium as well as dolomite. In the early days the soil’s pH was about 5.5, but now it is between six and seven while Olsen P is in its mid-30s. They have carried out all-farm soil testing in the past and this year they will repeat that to make sure it stays on track.

Another change in feed has happened in the dairy, with a meal-feeding system installed last winter. That is aimed at decreasing palm kernel and enables them to feed blends of feed that can be varied as nutrition and costs dictate. This past season they fed dairy pellets in the dairy and dropped 100 tonnes of palm kernel.

“It also means every cow is getting fed and we have less lame cows now,” Murray says. “We always reckoned we were getting a lot of our lameness because the cows were pushing and shoving around the troughs.”

In the future they will consider barley, meal or whatever is cost effective at the time and the in-shed feeding also provides the opportunity to get minerals into all the cows.

Two years ago they decided they wanted to make less balage because of the plastic wrap, the cost and also the round shape that made it harder to cart to the runoff. They bought a hay turner and will still make balage, but less. All balage plastic wrap has been recycled for years.

Wildlife issues

They cut about 8ha of silage on the runoff each year as well as making some on the farm out of surplus. This past season they made 50 truckloads of grass silage and 30 truckloads of maize silage. Pukeko love to dig holes in the plastic to get to the maize pit silage, so netting has to be placed over the plastic cover to keep them out.

Deer add to the wildlife problem, heading out of the neighbouring bush to graze pasture – at least they put venison in the freezer.

Their latest improvement to the farm is dung beetles and they have teamed up with four other Linkwater farms to distribute them through the catchment. They paid $6000 for two packs of beetles which were subsidised by the Te Horiere/Pelorus Catchment Restoration Project. The Ministry for the Environment has identified the area as an exemplar catchment and the Frosts have been actively involved in the project.

All properties throughout the catchment have had streams mapped and measured for clarity, nutrients, sediment and E.coli. That has created a baseline that can be used for a monitoring and evaluation programme, with improvements made where needed. The dung beetles are one way of improving environmental outcomes on the dairy farms by taking dung down into the soil. Not only will that reduce runoff, but also aerate the soil.

The first batch of their dung beetles arrived in November, with further batches released in January, February and the last in March. Four different species have been released that suit Linkwater’s climate and soils. Each species has its own seasonal activity and even day versus night activity.

Tanya says the farming community should benefit from their combined efforts and they are hoping the dung beetle population will multiply faster. In three to five years they will see how the population is tracking and possibly add another pack. They also plan to buy a pack for the runoff.

In their bid to protect the estuary at the edge of the farm that is part of Pelorus Sound, Murray and Tanya did the research and planted species specifically for the location. Last July’s flood wiped most of those plants out, so it is a project that is back to square one. This time they will plant further back from the estuary and hopefully the plants will get established before another flood.

Another goal of the business has been reducing bobby calf numbers. Sexed semen is used for the first three weeks of artificial insemination (AI) and Hereford semen is used over the poorer-producing cows. Angus and Murray Grey bulls then run with the later-cycling cows. The herd is made up of Friesian and crossbred cows, so they have buyers for the four-day-old Friesian bull calves as well as the beef-cross.

Photo albums show the progress on the farm during the past decade and Tanya says it is very satisfying to look at them and realise what they have achieved.

“It has had its challenges, but all in all we have loved and still love what we are doing.”

In-shed feeding enables the Frosts to have more flexibility with feed and use less palm kernel.