The Chubbs stick to grass for the cows on their Golden Bay farm. By Anne Hardie.

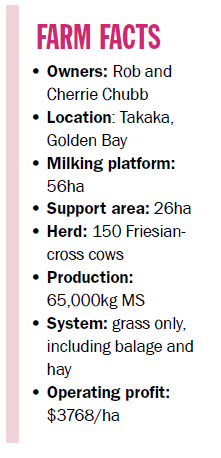

Rob and Cherrie Chubb run a simple, grass-based system on their small Golden Bay farm and consistently rank in the top five farms for profitability in the Top of the South. Their 56-hectare milking platform near Takaka milks 150 Friesian-cross cows that put about 65,000kg milksolids (MS) into the vat consistently each year and in the 2020-21 season, the latest available data, returned an operating profit of $3768/ha or $3.22/kg MS. The farm nudges into the top of a valley and sits on stony soils that are great for warming the soil up in early spring but are lethal to machinery. Rob describes rock gathering as a family tradition for Cherrie’s family that has farmed the land for about 70 years.

“We call them icebergs because you see a small stone on the surface and it’s just the tip.”

Years of rock gathering enables them to mow 90% of their paddocks now which means they can make balage to feed out during dry periods of summer or autumn, plus hay to fill the cows up in winter. It’s the only supplement the cows get through the year, mown from either the milking platform or the adjoining 12ha support block or the 14ha lease block just down the road.

“The cheapest thing you can grow is grass so we just grow the most grass we can with the cheapest method. I don’t get to eat lollies and chocolates, so I’m hard on my cows and they don’t get them either. We try to make them a nice boring life of eating the grass.”

They trialled maize one autumn and found the cost ruled out any gains. They also trialled palm kernel and got sick of lame cows, the wastage and dustiness of the feed. It required infrastructure and that was a cost. So they returned to grass and it is profitable. Cows head off to the support and lease block for winter and spend seven weeks there on saved pasture, balage and hay. The stony ground rules out winter crops even if they wanted them. Robb says the finance on the support and lease blocks is cheaper than sending the cows away on a truck for grazing.

A reliance on grass means they have to do it well. Thanks to a relative who was a surveyor, the farm is split into even-sized paddocks which makes rounds easy and also shifting the K-line irrigation. Then Rob came along with a civil engineering background and wanted to have more than just eye appraisal to help with pasture production.

“I bought a platemeter – maths and science – so I could see how much grass grew in every paddock every day. Then I got older and wiser and now I can just look at the grass.”

Residual is everything, he says, and by running a set round on similar-sized paddocks and achieving quality pasture, they know what their cows are eating. Total feed eaten for the farm during the 2020-21 season was 14.1 tonnes/ha and that same season the cows turned that into 1172kg MS/ha which averaged 446kg MS/cow. The whole operation, including young stock, consumed 15.9t DM/ha and 76% of that was pasture on the milking platform. Another 11% was grazing replacement stock on the support and leased areas, plus 9% for wintering the cows off the milking platform and 4% was supplements made on those support blocks and brought to the milking platform. To rely on pasture, they need irrigation and the Chubbs put down a well 11 years ago as they have no direct river access. They priced a pivot for irrigation, but they would have needed to remove most of the totara trees scattered around the farm and still require K-line in the corners of the paddocks. The regularity of the paddocks makes it easy to shift the K-line and Rob says it only takes an hour and 20 minutes a day.

“You have to have something to do. Otherwise you’d have to be at the beach swimming.”

Like many Golden Bay farms, their pasture is cursed with giant buttercup and it is a constant battle to keep it under control. Rob says they can hit it hard with Preside or its equivalent and that keeps the weed at bay for about 18 months and they need to be careful not to pug ground or the buttercup will take advantage of the broken ground. Tordon’s PastureBoss “certainly killed buttercup but also killed everything known to man”.

Targeting the yellow-flowering weed with herbicide takes its toll on clover though and it is always a balancing act deciding whether to spray or not. Hitting buttercup with herbicide is such an ongoing job that they have their own sprayer and do the job themselves. Topping the weed hard is another option when they have a year of major grass growth. Pasture is everything and Rob and Cherrie focus on protecting the soils so they can grow good pasture. Gateways are fenced off to protect the ground and springers are moved at least twice a day to reduce damage. For the past eight years they haven’t resown any paddocks because they have avoided damage. Prior to that, the entire farm was resown over four years. Keeping it simple on the farm means they don’t require much machinery which is why their current tractor replaced a 1973 model they had used for decades. Being efficient means ignoring salespeople and only buying what is necessary.

Rob says they do spend money on animal health, though good breeding over 40 years has resulted in healthy, structurally sound cows suited to the grass-only system. The herd comes from a predominantly Friesian base and they have moved to crossbreds for hybrid vigour, a smaller cow and to improve fertility. Initially they used Friesian and Jersey genetics to produce crossbred cows, then switched to a combination of Friesian, Jersey and crossbred semen a couple of years ago.

Mating is a DIY job where they carefully select each bull for each mating to maximise the genetic gain for each individual. After three weeks of artificial insemination (AI), Angus bulls go into the herd. When they were transitioning the herd from its Friesian base to crossbred cows, Rob says there was an obvious difference between the black and white cows waiting for their feed and the crossbred spread out around the paddock with their heads down.

Cows are milked twice-a-day through the 16-aside herringbone dairy until the middle of January when the Chubbs switch to once-a-day to reduce heat stress in the animals. Rob says the cows can hold their milk so it seemed a no-brainer to milk just once a day and they keep to that milking frequency through to the end of May.

Their son, Oscar, joins them on the farm between April and October and Rob concedes they are labour inefficient. It means they “only work half the time but do it every day”.

“A good day on our farm is getting up, milking the cows, putting them in the paddock and walking away.”