Grazing precision = profit

Pasture management has always been a prime focus on the 930-cow, Mid-Canterbury dairy farm owned by the Blair family, but the Pasture Pro update to the Halter management system has sharpened that focus to the point they’re slashing bought-in feed and improving onfarm productivity.

Words Anne lee. Photos Michael Lahood.

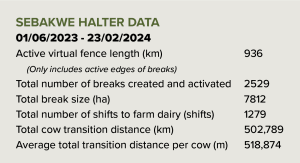

Daniel and Hanneke Blair run the 283ha flat Lismore property, Sebakwe Farming, between Geraldine and Ashburton, with three full-timers and one part time staff member.

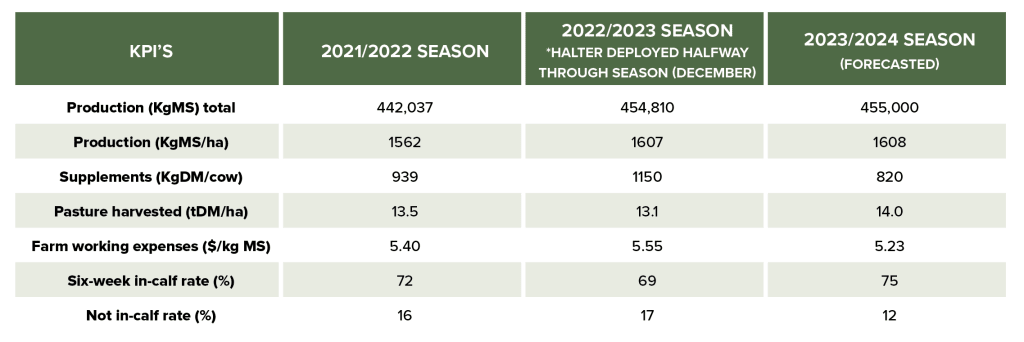

This season, Daniel expects bought-in feed is likely to be close to 720-820kg DM/cow, well below previous seasons where it typically sat closer to 1t DM/cow.

They put Halter collars on their cows in December 2022, initially as a means to reduce workload on staff and create a little time for off-farm activities, but the benefits have gone well beyond expectations for both the farm team and for animal performance. The Pasture Pro update has been a game changer, Daniel says. “We’ve been able to drop out the spring and most of the autumn baleage this year and hone pasture management to get better pasture harvest from the cows so we’re not wasting home-grown feed,” he says.

A reduction of more than 200t of palm kernel was achieved before Christmas plus about 82t DM less baleage fed, which will bring savings of more than $100,000 alone. It’s equivalent to harvesting an extra 1t DM/ha of pasture, Daniel says.

Increases in farm working expenses were held to within a 2.7% increase last season – an impressive feat given onfarm inflation was sitting at close to 15% year-on-year. This season, those costs are expected to drop 5.8% showing the power of improving home-grown feed utilisation.

On top of the drop in bought-in feed, they’ve also seen a significant jump in reproductive performance which Daniel attributes to not only the ability of the system to identify cycling cows, but the improvement in pasture management at crucial times.

DairyNZ calculations estimate the farm’s improvement in six-week in-calf rate and drop in not-in-calf rate are worth $68,820 in additional profit. “We’re managing cows over the transition period (pre and immediately post calving) so much better. At that time of the year it’s just incredible what you can do.

“We used to have someone tied up from after breakfast till after lunch just doing fences, setting up breaks for the different herds, for night breaks and morning breaks and winding up the kale break. But now – well now we sit there after breakfast with the boys having a coffee and a chat and we just set them up on the app. The best thing is managing the colostrums and getting their rumination up because we can give them multiple breaks in a day.

“The research has found that shifting them stimulates their appetite, but in reality, if you’re putting up fences – who has time to be going out moving them six or eight times a day? We can just set up the app to open up a little bit more and a little bit more as the day goes on. We can set up recovering well and recovering poorly groups and if they’re recovering well, they can go straight onto twice-a-day (2AD) milking once they’re out of the colostrum group, but if they’re not recovering well, we milk them once-a-day (OAD). If any 2AD cow takes a bit of a dip, we will flick her back into the OAD group.

“In previous years, before we had all this information, we just milked everything OAD for 14 days and we lost a bit of milk in the vat that way. This way, with more accuracy, we’re up 3000kg MS for August.”

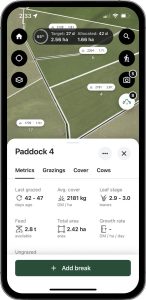

Insights such as the leaf emergence rate had the team talking during the autumn period. “We know that grazing at the 2.5-3rd leaf stage is optimum because cows are grazing paddocks when they’re at the optimum in terms of quality and quantity, but it’s easier said than done sometimes.

“We were on a 30-day round in early March, but the app told us the leaf emergence rate had jumped to 33-days so I said ‘now’s the time we need to push our round out a little more’ so we’re grazing at the right time – it just gives you that bit more precision and that can make so much difference to intakes and production.”

The app’s residual and pasture cover estimates are highly accurate, Daniel says. “We don’t do pasture walks any more – so that’s three hours a week we get back – and then the accuracy – that human error is just gone. Previously we’d have someone setting up breaks and you’d look at one every now and then and think heck that looks like it could be 100m too short, but then no one’s got time to go and shift it out and move the others so you wear it for that break and probably lose a bit of milk or have to feed a bit more supplement.

“That just doesn’t happen now, because, as you set the fence on the app, you’re seeing exactly what you’re allocating for each cow and you can move the fence to get it absolutely bang on.”

Daniel says it’s farm policy to take photos of residuals in the app after each grazing. “We go into the paddock in the morning once it’s light and we walk on an angle across the paddock taking photos every four metres. That gives you a very accurate measure of the residual. We do the same in the afternoon.”

In early March the residual was set at 1520kg DM/ha. “If it comes up at 1580 or 1600kg DM/ha it knows there’s another 60-80kg DM/ha available there for the cows when we come to setting up the next break. We know that extra is there and we’ll allocate them say 3kg of new grass and they’ll get into that and then go back into that residual paddock for a set amount of time so they clean it up.

“After that set amount of time we’ll schedule in another break for the rest of their allocation. We can go and take a look and drop the virtual fence if we think they’ve cleaned it up ahead of time. That accuracy … you just wouldn’t do that if you were winding up fences.

“It has increased the intensity of our operation, but in a good way. A way where we can really hone our pasture management and that’s where we’ll make and save our money at the same time.” The app will tell Daniel how much supplement will be needed to bring total intakes up to the allocation he has set for his cows. For instance, if he’s on a 30-day round and he wants his cows to be consuming 18kg DM/cow/day the app will ensure his break size meets his round length requirement and, based on what the app knows that pasture break will provide for the cows, it lets him know how many kgDM need to come from supplement.

That’s possible because the app knows what growth rates are thanks to climate data, machine learning the farm, residual data and latest grazing information.

“You can see all the data for a paddock or an area that you might be using as a break right there on the app – the last residual, the cover – which it can estimate right down to a few metres square, the date it was last grazed, everything you could want to know.”

Managing the winter kale crop has also become ‘a breeze’. “We were able to give them four or five smaller breaks a day as opposed to having to cut breaks ahead of time, put up fences and then let them through and give them one larger break a day. We worked out that we saved about 1.5kg DM/cow/day through the better utilisation that allowed.”

It’s also given the whole team a renewed enthusiasm. “Darryl Sturm is our manager, he’s 57 and he’s been dairying all his life. He just loves this and he uses it to help train the others. We use the app to spark up some great conversations about why we’re doing something and what we’re doing – round lengths, residuals – everyone really gets their eye in on that. And it means we have more time to be doing the really important things onfarm and getting a bit more time for the things we want to do off-farm as well.”

There’s more interest and more freedom all while creating more profit from well-fed, healthy cows.

Game changing pasture AI

Artificial intelligence (AI) could well become even more of a factor in farm productivity given the step changes Halter’s latest updates are making to pasture management.

Halter Partnership Manager Steve Crowhurst explains how machine learning, satellite imagery, weather information and collar GPS data; combined with NZ farmer expertise in pasture management, have enabled Halter’s engineers to create a ‘game changing platform to manage pasture’.

Pasture Pro came out as a free update within the app for Halter farmers in time for spring last year and already it’s not only saving farmers significant money in terms of less bought-in feed, it’s adding to the revenue line too, with increased milk production through better pasture utilisation. “We know that farmers have been facing cost and inflationary pressure, and one of the major costs in the budget is bought-in feed. We also know that one of the biggest drivers of profit to the farm business is pasture utilisation.

“But current pasture management methods can be limiting. Accurate pasture information is not coming through in real time. It can also be labour intensive and traded off against other jobs on the farm. Although there is so much fantastic research from NZ pasture scientists to tell us when the optimal grazing times are, and superior grazing strategies, the data was too hard to action in reality.

“Initially Halter’s virtual fencing and virtual herding meant farmers were able to be extremely precise when setting breaks and moving cows. Now with Pasture Pro, we’ve gone that next step and can inform farmers exactly how much cover is in the paddock, how much they are allocating, and if the ryegrass is at that optimal two-and-a-half to third leaf stage. This means farmers are consistently hitting the right residuals, growing and harvesting more grass.”

The company’s developers and engineers have been listening and working closely with farmers to come up with what he believes is a revolutionary tool.

Today the power of machine learning means that huge amounts of data can be used to present highly accurate, insightful information. “We have this fantastic combination of world-class pasture farmers and pasture scientists in NZ, along with world-class data scientists and engineers within Halter – that’s what’s made Pasture Pro possible.”

Today the power of machine learning means that huge amounts of data can be used to present highly accurate, insightful information. “We have this fantastic combination of world-class pasture farmers and pasture scientists in NZ, along with world-class data scientists and engineers within Halter – that’s what’s made Pasture Pro possible.”

Pasture Pro includes multiple tools such as post-grazing residual readings simply by taking photos within the Halter app on a farmer’s smartphone.

The app shows average pasture cover across the farm and per paddock, growth rates, leaf stage information and the allocation per cow as a farmer is setting a virtual break. This means farmers can adapt and alter their feed strategy relative to the changing conditions each day onfarm with a fluid round length.

Steve says the AI model is continuously evolving. Halter’s focus for the next few months is further development of the model to enhance the accuracy even more. The model will fuse data sources and remote sensing technologies that look at everything from weather conditions and grazing practices to soil composition and drainage properties.

Steve says although the back-end system is hugely complex, the collaboration between Halter’s world-class designers and farmers has resulted in an intuitive app experience for farmers. “The app’s been designed to be user-friendly and intuitive so, at the front end, it’s giving you just the insights that are most important.”

Pasture pro is a tool supporting the key decisions and tradeoffs farmers need to make themselves. “It’s empowering those decisions by giving the information in a very user-friendly way – it’s giving farmers insights that can be easily actioned through the use of virtual fencing that optimises feed allocation. What is exciting is how the current limitations we see in farming have now been removed, allowing farmers to advance their pasture management and bring their operations into a new era of high performance and productivity.”

Visit halterhq.com