Growth potential for Wagyu

Michael Schat gave up contract milking to go into the Red Wagyu business boots ’n’ all and is making the most of opportunities that come his way. By Sandra Taylor.

Last spring, Dunsandel farmer Michael Schat almost single-handedly reared 2000 Red Wagyu-cross calves to 110kg on his small lifestyle block.

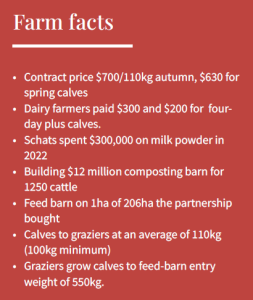

From July, he will also be operating at the other end of the supply chain, finishing more than 3000 Wagyu cattle annually in a one-hectare covered, composting barn at Aylesbury, about 20km from Dunsandel.

From July, he will also be operating at the other end of the supply chain, finishing more than 3000 Wagyu cattle annually in a one-hectare covered, composting barn at Aylesbury, about 20km from Dunsandel.

The barn, which will have 1250-head capacity, will be home for the Wagyu for a minimum of 100 days. Construction will soon get underway on the $12 million facility Michael is building in partnership with Southern Stations Wagyu, an Australasian subsidiary of StockCo.

The former dairy farmer sees huge opportunity for Red Wagyu beef in a world crying out for the rich, marbled meat that sits at the very premium end of the market. In Wellington in May, Wagyu beef was retailing for $199.99/kg.

Michael says this premium can flow right along the supply chain, from the dairy farmers who use Red Wagyu genetics across their non-replacement cows, through to the rearers, graziers and finishers.

Michael, his wife Leigh and their two sons Charlie (9) and Liam (7) live on the 8 hectare calf-rearing block at Dunsandel, about 50km south of Christchurch.

It’s on this block that the inventive Michael initially built a 340-head eco-build tunnel house calf-rearing shed. This was followed last year by a larger 800- head tunnel house. Within these sheds, he has set up ingenious feeding systems that allow him to rear so many calves, assisted only by a part-time staff member at the peak of the season.

To justify this investment, forward contracts with Southern Stations Wagyu were essential and Michael was paid $700/110kg calf for autumn and $630 for spring-born calves. The dairy farmers supplying the calves, which were a minimum of four days old, were paid $300 and $200 respectively. Calf-rearing costs last season were high, so Michael needed a high through-put model to make calf rearing a viable career option.

“We were confident to buy the milk powder and the meal, knowing these calves were sold at a fixed price,” he says. Last year they spent more than $300,000 on milk powder alone.

Changing career

Michael dipped his toe into the Red Wagyu supply chain three years ago, rearing just 180 calves for Southern Stations Wagyu while still working as a contract milker.

This grew to 1000 calves in 2021, and last year Michael and Leigh made the decision to finish up their contract milking and go into the Red Wagyu business boots and all.

This meant building the second calf shed, which Michael was scrambling to finish as the first calves arrived last spring. They invested in a grain silo and dispenser (a converted fertiliser hopper), a JCB loader for spreading straw bales (it can spread a bale in less than a minute), a gas califont for heating the milk, and a large-scale milk-mixing unit. During spring he was mixing up to 8000 litres of milk a day – that’s 70 bags of milk powder.

Along with milk and feed dispensing systems designed by Michael, this set-up allowed him to feed 2000 calves in two-and-a-half hours.

Despite dealing with such large numbers, Michael stresses the importance of not cutting corners in any aspect of the rearing process and this means ensuring the animals have nutritionally balanced feed and fibre that is so essential for rumen development. He collects the four-day-old (minimum) Red Wagyu-cross calves from dairy farmers from the Canterbury area and the calves are put into pens of 50. They stay in this cohort until they are sent off to their graziers at an average 110kg (minimum 100kg).

It is vital the calves have had colostrum and are healthy before Michael collects them. Southern Stations Wagyu monitors this by visual inspection, DNA testing and doing random antibody blood tests to ensure farmers have been following best practice.

While Wagyu calves seem to have a reputation among some dairy farmers for being hard work, Michael disputes this. He says Red Wagyu are a completely different genetic package, being similar in size and type to a Friesian rather than an Angus or Jersey calf.

“Care and attention to detail will go a long way.”

The calves are on straw bedding and new bales are rolled out daily. Not only does this provide warm, dry bedding, the calves chew on it and it’s an important part of their diet to complement the grain feeding and facilitate the growth of the papillae in the rumen.

Last season wasn’t without challenges and last year Michael had to deal with an outbreak of rotavirus and coronavirus.

It took a concerted effort to minimise losses to just under 2% and required feeding affected calves up to five times a day with an immunity milk mix and warm electrolytes.

Michael says it was the coronavirus that killed the calves very quickly and they had to be on top of the disease to minimise its spread. This meant asking supply farmers to hold calves for a few more days, which they were happy to do. Michael believes the diseases were exaggerated by using milk powder rather than whole milk, and he is negotiating with a whole-milk supplier for next spring for blending.

Laying down fat

While four weeks in the shed is recommended best practice, Michael held some calves in the shed for six to seven weeks and felt they did so much better, especially as it was such a cold, wet spring.

The calves were then run out into small, sheltered pasture paddocks in their existing mobs. Here again Michael has designed a milk-feeding system that allows him to feed a large number of calves without having to go into the paddock.

The calves were weaned at about seven weeks or 70kg, but continued to have ad lib access to hay, balage and meal, which drove daily growth rates of up to 1.5kg/day.

Michael stresses the importance of a high starch diet balanced with protein and fibre to help the calves start to lay down the fat that is the essence of Wagyu beef.

Many Wagyu rearers use grain to grow the calves past 110kg and up to 200-250kg. This also helps their ability to marble and lay down fat.

Once at an average of 110kg (100kg minimum), the calves are sent off to graziers for growing out to their feed-barn entry weight of 550kg.

Michael says the attention to detail at the calf rearing stage lays the foundation for the calves to continue to grow and lay down fat, which makes the graziers’ job a lot easier.

The Red Wagyu calves need to have starch in their diets throughout their first year, but this can be dropped in the second year until the animals are ready for the feed barn.

Feed-barn finishing

The cattle will spend a minimum of 100 days in the feed barn on a grain-based diet with the aim of producing an average 400kg carcase.

As well as getting the animals really fat, the high starch diet helps replace the yellow fat (taint from pasture) with the bright-white fat favoured by the Wagyu and grain-fed market.

The feed barn at Aylesbury will be part of a 206ha farm the partnership has bought. As well as the feed barn that will hold 1250 head, they will grow young Red Wagyu on pasture and necessary supplements to optimise growth rates.

Michael says the focus will be on grain assisting the young stock to maximise performance and activate their genetic ability to marble well later in life.

While construction of the feed barn is yet to get underway due to a minor consent hold-up, Michael says it will be state-of-the-art deluxe finishing set-up with a carefully managed composting barn. He says they have been working alongside Environment Canterbury to ensure the barn meets all required environmental standards.

“The system is driven by very high environmental standards and outcomes and a lot of capital has been invested in achieving these,” he says.

“ECan has very robust criteria that has to be met and this should give the public confidence in what we’re doing.”

The animals are toll processed at 400kg CW by ANZCO for Endeavour Meats, an Australian-based company that looks after all the shipping and marketing.

Working in partnership

It was Southern Stations Wagyu who approached Michael about going into the partnership with them at the grain finishing end of the supply chain.

While running a feed barn was never on his radar, he did learn about best-practice feedlot finishing when, aged 19, he went to Australia and worked for a family considered to be at the top of the grain-feeding game.

“I was fortunate to be taught from the ground up and it was a lifetime’s worth of knowledge.

With the first animals expected to arrive at the barn in July, Michael will have his hands full setting that up while getting the first calves into the rearing sheds.

Ultimately, he and the family will move to Aylesbury to focus on grazing and the finishing operation and give others an opportunity to rear the calves.

Southern Stations Wagyu will handpick people to rear the calves and this will help those people who are prepared to go the extra mile with these animals to grow their businesses, he says.

“It’s been a fortunate move for me. I’m 37 and it’s a good time to be getting my teeth into something and growing my equity.

He says while it’s big numbers, it is underwritten by the Southern Stations Wagyu supply chain.

“It’s a huge opportunity for us.”

While Michael always thought he would make a career out of dairy farming, he is now pleased to have taken a different path and encourages others to step outside their comfort zones. He encourages people to have a go and “break the mould”.

Attention to detail

Michael talks a lot about quality assurance and best practice throughout the Red Wagyu supply chain and this is closely monitored by Southern Stations Wagyu, but he says farmers are financially rewarded for their attention to detail and hard work in growing these high- worth animals.

For the dairy industry, which is grappling with the issue

of bobby calves, the Red Wagyu are an excellent solution in that the calves are sold on forward contract and an earlier AI means a compact three-week in-calf rate. Also, with herd management systems, which allow cows to be drafted automatically for AI, there is no need to use bulls over cows, which is a big saving in itself.

Similarly, the rewards are there for calf rearers and

graziers. Michael says there are a range of relationships

and contracts available through Southern Stations Wagyu,

but he believes the opportunities are there to really lift

per-hectare returns and diversify farms, particularly for calf rearing.

At the other end, Michael is confident that the market for premium Red Wagyu meat will continue to grow.

Wagyu has been around for a long time, he says. Red

Wagyu is strong because Southern Stations Wagyu sells it into a range of markets around the world, not relying on any one country or small markets for its sales.

Key points

• Former contract milker

• Last year reared 2000 Red Wagyu calves

• This year finishing 3000 Wagyu cattle

• Forward contracts give security

• In partnership with Southern Stations Wagyu

• Premiums throughout the supply chain

• Attention to detail critical in Wagyu system

- First published in Country-Wide June/July 2023.