Investing in the right technology

Data is only as valuable as one’s ability, or willingness, to use it. Farmers investing in technology for their farm dairy require functionality and data that adds to their onfarm business decisions. Words Sheryl Haitana.

Farmers are upgrading their farm systems with technology and data solutions, but there needs to be clear evidence the data is adding value to their bottom line. If farmers are sold a product that doesn’t have a clear return on asset, or isn’t adding value in a practical sense to their daily farm operation, that trust is broken.

“We don’t want to be selling data for data’s sake,” SenseHub Dairy national sales manager for technology solutions Austin Heffernan says.

“At some stage it has to pay for itself. Information and technology provided to customers has to be meaningful and give useful insights, otherwise we are just slamming them with information.”

A new technology might come with the flashiest bells and whistles, but the most important aspect is still functionality, he believes.

“If the technology is not drafting the cow that needs to be drafted, or the accuracy of the system is not as good as it should be, farmers will lose trust in technology to do the job.

“If we look at the roadblocks to farmers uptaking technology, one has been the value proposition discussion. A lot of people will argue they’ve done a good job without the technology for 30 years, so why do they need it?”

‘Herd testing is accurate, but it’s a snapshot of one day. That one day can be influenced by a number of factors. This data gives you a constant window into what individual cows are producing.’

The answer is that the technology consistently does a good job and removes a lot of the time and effort for staff, Austin adds.

“Our technology will reliably and consistently draft the animal out that needs attention.”

Some farmers may see technology as a threat to what they’re doing onfarm or question whether the next generation will be relying on technology too much and not have the skills.

But by taking care of some of the daily jobs onfarm, it can actually help to educate farm staff and it gives people space and time back to concentrate on the jobs where they can really make a difference, he says.

When farmers are considering investment into technology onfarm, they should be driven by what they want to achieve; how that technology will work with their current set-up – but also how they want their business to operate long term, Austin explains.

“The farmer needs to understand what they’re hoping to improve by using the technology. What are the areas of improvement where they can get some easy wins on their farm, where technology can help, and where they want to go in the future.”

The technology they buy today also needs to work with future equipment or technology they want to invest in.

The technology they buy today also needs to work with future equipment or technology they want to invest in.

MSD Animal Health’s SenseHub Dairy is an evolving ecosystem connecting animal behaviour monitoring, milk monitoring, drafting gates, and in the future, milking-related automation, all on one easy-to-use, cloud-based platform.

The latest addition is MilkPlus and Somatic Cell Count (SCC) sensors, which can both be installed into any dairy shed and links to the other SenseHub Dairy products, including the monitoring collars (previously Allflex) and Protrack.

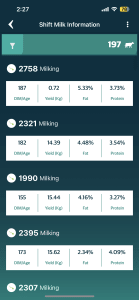

The SenseHub Dairy in-line MilkPlus Sensor monitors yield, fat, protein, lactose, blood, and conductivity – providing farmers with milk trends for individual cows, groups or the entire herd.

“We believe we have the only commercially available sensor to do that and fit any dairy shed. In New Zealand, we get paid for fat and protein, they’re big drivers for breeding selection and culling decisions.

“Herd testing is accurate, but it’s a snapshot of one day. That one day can be influenced by a number of factors. This data gives you a constant window into what individual cows are producing.”

The milk sensors are suited to farmers already comfortable using technology and using data to make decisions onfarm, Austin says. With the milk production insights, farmers can make faster, more informed breeding, feeding, udder health, dry-off and culling decisions optimising productivity and animal wellbeing.

“You are looking for the cows who are the outliers, and the cows who have had dramatic change.”

The SCC sensors can be installed on their own or with MilkPlus sensors, and again fit any dairy shed.

“The SCC sensor is an in-line sensor, that is effectively an in-line rapid mastitis indicator.”

The SCC sensors are fitted with an Optical Warning Light (OWL) and within the first two minutes of milking, an alert light will go on if the cow’s somatic cell count is up.

Historically this technology has not been available in herringbones with the complication of identifying cows, but the MSD Animal Health research and development (R&D) department with the SenseHub Dairy identification solution has solved this problem.

“We have now got a very reliable identification system for herringbones so we can now start rolling this technology out in herringbone farm dairies. We are agnostic when it comes to what brand, make or type of equipment is in the farm dairy.”

The OWL lights are very useful in the herringbone because they can be easily seen by the person milking the cows.

“Our R&D department is investigating how to have another level of alert in a rotary farm dairy at cups-on.”

It is one example of how the MSD Animal Health, who own SenseHub Dairy technologies, Allflex and Protrack, are continuing to invest in system upgrades and focus on the practicality of the technology and how it is working in a farm dairy, Austin points out.

Visit sensehub.co.nz