A young Canterbury farmer’s succession has followed a challenging route. Anne Lee reports.

It’s hard to know what John Totty’s forebears would have thought of the innovative 10 in seven days milking schedule now in place on the farm they settled 100 years ago.

But there’s no doubt John’s pretty sold on it. Maybe it’s his adventurous spirit, evident in the seven years he spent as a hunting guide and horse wrangler in the Yukon or maybe it’s his savvy head for numbers gained while completing a degree in finance and accounting from Otago University.

Whatever it is, the 30-year-old is up for a challenge, happy to look outside the square and energetically explore a farm system that suits the Canterbury dryland location close to the foothills and ticks the boxes in terms of people, animals and very importantly profit.

John says he always knew he wanted to return to the family farm which is celebrating its centenary.

His great, great grandparents had been dairying near Clandeboye before setting out to find the 90-hectare Staveley farm that’s been in dairy ever since.

Over the years it’s grown to 333ha and the dairy farm has expanded although at times there’s also been some cropping, up to 3000 sheep and even a spot of goat milking.

John started buying into the farming business eight years ago, but after his father Ian died tragically falling from a shed roof in 2016, he bought the home farm with some help from family loans and of course the bank.

Making a reliable, good profit is essential.

“I’m pretty much on the wrong side of all the banking ratios so getting debt down is a priority.”

John didn’t jump straight back into day-to-day farming, instead asking the lower order sharemilker on the farm to stay on for another year while he worked on a large-scale farm at Dunsandel.

“I wanted to get outside experience and see how others did it. Even though I got offered a 2IC role I went in as a dairy assistant and worked my way up pretty quickly from there.”

He sought out information from trusted sources, reading voraciously (including the Dairy Exporter), connecting with DairyNZ, completing PrimaryITO training and surrounding himself with experienced, respected advisors, both rural professionals and farmers. At the same time, as farm owner he was working with the sharemilker on the home farm making key strategic and management decisions.

The farm had been milking 750 cows at peak producing about 265,000kg milksolids (MS) but John could see there were some fundamental farm design factors holding back productivity. John’s father had put in two herringbones in 1996 and 1997 – a 36-a-side on the Lawnhayes block and a 20-a-side on the neighbouring Bushside block. Because the farm had been added to over the years some of the lanes took the “long way round” getting back to the farm dairies.

“A lot of the corners were being used as runoff and it just wasn’t easy to move cows around.

“There were still a lot of sheep paddocks so when I came back, we re-laned the whole farm and gutted three blocks to re-fence them on to the new lanes.

“A lot of paddocks were still set up for a 200-cow herd – that could mean up to four shifts a day.”

The redesign was done with the help of experienced farmer friends and advisors.

“It’s good to have fresh eyes – it’s hard when you’ve looked at a farm your whole life and think that’s just the way it has to be.”

The result was an hour less walking for cows each day on a TAD milking system.

In his first season back home in 2017/18, John milked TAD from the outset, expecting to drop back to once-a-day later in the autumn.

But from the second week of November the typical spill-over rain from the Nor’ West dried up and, heading into the second week of December with no rain on the horizon, he made the decision to send his biggest Friesians off-farm to friends with irrigation and put everything else on once-a-day (OAD).

“We bought some palm kernel in and used silage we had on hand but it wasn’t till March 6 that we brought the Friesians back.

“They were pumping on TAD and our other Friesians were back on TAD by then too.

“The 500 cows we had on OAD stayed on that right through – mainly the Jerseys.

“But they just didn’t drop from the 1.5kg MS/cow/day they’d initially dropped to when I put them on OAD.

“We managed to do the same production for the season as the sharemilker had done with the same number of cows.

“I started thinking maybe the system we had wasn’t quite the right one for these cows here.”

So, he started researching and asking advisors who the best OAD farmers were.

“A lot of people doing OAD that I talked to had dealt with the lower production by cutting a staff member but because we had two sheds, I struggled to see how I’d cut a whole staff member and I needed to maintain profit.

“We could have milked OAD at each shed, just different ends of the day but we wouldn’t get any of the people benefits I was looking for in creating a more sustainable place to work.”

He liked the look of 3in2 particularly if it could be done at more “normal” milking times as research was suggesting. So he tried 3in2 in the autumn in 2018/19 and in 2019/20 went 10in7 from January 15.

The cows held production and even lifted a little giving 340,000kg MS from 900 cows for that season.

That gave him confidence and this season he’s not only using research findings to base his system on, he’s also helping build research knowledge, joining the DairyNZ flexible milking project in the second year of the study as one of six pilot farms.

Over the past three seasons John has lifted stock numbers to 1050-cows, moving to a more Jersey herd by both breeding and buying in good quality calves from well-known Jersey breeders Steve and Nina Ireland.

The new system in action

This season planned start of calving for the main herd was August 10 with most cows OAD for the first three weeks of their lactation.

Cows are calved on Lawnhayes and milked through the 36-aside dairy OAD until 400 cows have calved – around August 15.

The Bushside farm dairy is then started up and 300 cows moved across to that block.

“When we get to 300 cows at Lawnhayes we change the colour of the paint we use to show cows are clear to come out of the colostrum mob.

“That means we can easily identify the 300 that need to go over to Bushside and on Lawnhayes we know when to reset the next three-week OAD group.”

They milk OAD for about five weeks at Lawnhayes and then go to the 10in7 programme. Cows going to Bushside go straight on to 10in7.

John says that based on the research showing there’s only a small (about 2%) reduction in milk production from OAD milking in the first three weeks, he’s used the tactic as a way to manage workload on his four staff through the early and peak calving period.

“We actually had time to do the refencing we needed to do in the afternoons on both farms through early spring.”

Milking started at 8am initially with the aim to have everyone home by 5pm and, as more cows calved, milking time gradually moved earlier to keep the same home time.

The earliest was 5.30am cups on.

10-IN-7

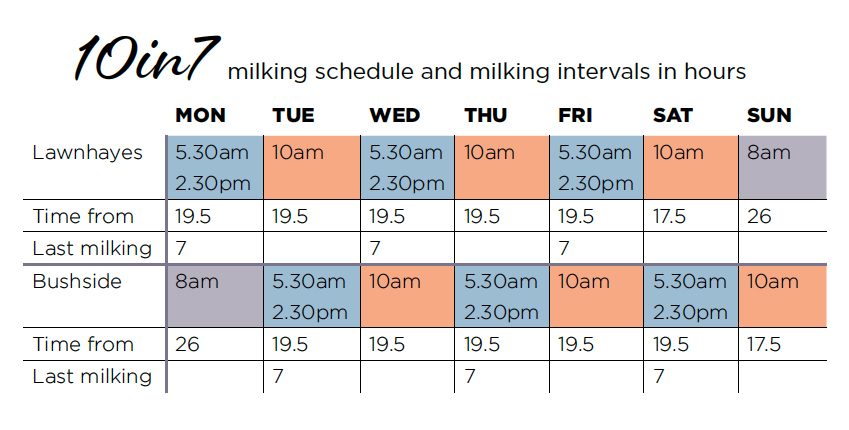

The 10in7 programme is a combination of 3in2 and two consecutive OAD milkings to allow for OAD at a weekend.

In John’s case the Lawnhayes block starts the week with two milkings on a Monday at 5.30am and at 2.30pm with Tuesday a OAD milking at 2.30pm.

Wednesday is TAD, Thursday OAD and Friday TAD. Saturday’s milking is at 10am and Sunday’s at 8am.

“It’s so good in the weekends. People can go out on a Friday and Saturday night if they want to. They can catch up with friends.

“We just do the absolute must-do jobs on those weekend days so once milking’s over people generally head home.

“The other great thing is that every week is the same.

“On a full three-in-two schedule, each week is different and it can really confuse people – they can’t quickly remember when they’re coming back from days off what time the next milking is.

“It also makes it tricky to plan things out in advance whereas we all know, even four months ahead, what the milking times are on any given day.”

John has staggered the other farm dairy so that Bushside has its consecutive OAD days on Sunday and Monday.

Only one person is required for milking there for the 380 cows. He’s planning on extending the farm dairy there and fitting automatic cup removers to make sure they keep it to one person needed for milking.

John says the 385,000kg MS target from 1000 cows is firmly in his sights using about 100kg DM/cow of supplement.

About 100kg DM/cow of silage is made on the milking platform during surplus and fed back to cows through the hot, dry months of January and February but they don’t feed out during autumn, instead using homegrown fodder beet as cows are transitioned up to 4kg DM/cow.

About 300 bales of silage are exported off farm for wintering. He meets with his two senior staff twice a week – the first meeting to review covers, with the farm plated every week, to look at where the cows have been, plan any silage cuts and make paddock and feed allocation decisions. Managing pasture on the dryland Canterbury farm is an absolute priority to ensure maximum, high quality pasture harvested by cows. The second meeting will discuss how that’s tracking, cow condition and any other activities coming up. They have three full team meetings a week too and have begun using the Kanban system (see Dairy Exporter August 2020) to manage farm tasks.

Cows peaked 10% lower this year at 1.9kg MS/cow/day on Bushside and 1.8kg MS/cow/day at Lawnhayes where most of the Friesians and lower BW cows are run.

“It’s hard to say how much of that is due to the milking frequency changes or because of the season – a lot of people are reporting a lower peak and then a big drop from peak this season.

“Compared with last season though our production is 14% up to date with 100 more cows.”

He’d synchronised mating for his heifers’ last mating so they had a compact calving, starting before the main herd and he’d also bought in 60 earlier-calving cows from the North Island which helped improve production for the first two months by 30%.

Cows have held daily production well through into early-December with John actually seeing a slight per day uptick.

“We had thought we might get a 5% reduction in milk production off the 390kg MS/cow, excluding calf milk, we did last year.

“But we’re still on target for 385kg MS/ cow which doesn’t include the calf milk we took out.

“That would push production up over 400 if we put that back in.”

Having enough vat capacity for the milking following the longer interval is something to be aware of, as is the need to ensure milk chilling systems can handle the additional volumes, he says.

With the extra 100 cows total production going to the factory will be up by about 34,000kg MS for no extra cost.

“I’m pretty tight on costs – we don’t spend money unless it’s going to give us a return and we’re on track for $4/kg MS for farm working expenses.”

Cow condition has been exceptional this year. The season has been relatively good but unlikely to have contributed largely to the gain in cow condition so John is putting much of the improvement down to the system change. Better cow condition has already brought savings.

For the first time he’s been able to use no intervention to get cows cycling at mating this year – last year he did 14%.

That’s been helped too by his decision to only use bull matings at Bushside and no AI. He’s organised the herd there to include his bottom 30% BW cows, anything he doesn’t want a replacement out of, cows with unsuitable udders, recurring feet problems or anything likely to be on the cull list.

“We’ve also made savings on power using 10in7 but it’s hard to say exactly how much because although we’re doing 33% fewer milkings some of the milkings are longer.

“Fewer milkings also means we’re using less fuel and maybe less repairs and maintenance eventually.

“We’ve definitely seen a drop in lameness – it’s dropped by 50% or even more.

“Last year we used the Healthy Hoof lameness app so we’re recording everything.

“I think we may see benefits in autumn and winter too because I think we’ll see cows hold their condition better through autumn – which means we’re not likely to go OAD at all through the autumn and cows will be able to milk on longer.

“We usually condition-score the cows to create wintering mobs but I think we’ll have fewer lighter cows and there will be a saving on winter feed.”

There are also those less tangible benefits that help cut costs and improve efficiency – factors such as staff retention and improved engagement. He runs a seven-on two-off, seven-on-two-off, seven-on-three-off roster and John steps in to milk and cover days off or holidays.

Farmers often cite worries with getting artificial insemination (AI) technicians when they need them when they’re considering going to three-in-two milkings.

“I think that comes from when people were sticking really closely to the milking intervals that meant they were milking at 10.30pm at night but we haven’t had any trouble with the milking timings we’ve got.”

John says the AI tech is happy to get to the farm at 12.30-1pm on the weekdays they are milking OAD and 9am on the days they milk twice. On the weekends it’s also after the tech’s other farmers so fits in well.

He’s putting Jersey across all of his cows because he believes they’re suited to the system and the dryland, low input, situation.

Three-week submission rate was 91% and based on returns he’s hoping mating results will be improved.

Cell count and mastitis haven’t been a problem this year despite John only using teat seal at dryoff last year.

“We only had four cases of mastitis in the first 680 cows calved and we’re sitting around 80-90,000 cells/ml but I’m confident we’ll run at about 70,000.

“Generally, I’d have to say the cows look better – they spend more time in their paddock grazing, more time resting and doing the things cows should be doing.

“It’s great to see even older cows kicking their legs up and running around, those are some of those intangible benefits, I guess.

“I don’t think you’ll see us going back to twice-a-day any time soon – there just seem to be too many positives here.”

Farm facts:

Location: Staveley, Canterbury

Cows: 1050 Jersey, Jersey cross

Total area: 440ha

Effective area: 322ha pasture plus crop for transition

Production: 385,000kg MS (budgeted 2020/21)

Supplement: 100kg DM/cow bought-in

FWE: $4/kg MS

Milking schedule: 10in7 with OAD for first three weeks of lactation

Irrigation: none

Stock reared: 600 calves including 200 Jersey 2-year-old bulls

Support block: 40ha

Farm dairies: 36-a-side and 20-a-side

Staff: four plus runoff manager and calf rearer.