Anne Hardie

From a micro fromagerie in Golden Bay, Gabrielle Kervella and Alan Cockman are using traditional methods to produce cheeses for their local community and see opportunities around New Zealand for budding cheese makers to do the same.

They are the first cheese makers in the South Island to produce raw milk cheeses, drawing off decades of experience working with milk products and now they want to pass those skills on to others in the same way cheese makers have done for generations. Both have a long history with cheese that began as apprentices training at the apron skirts of quality cheese makers and starter makers (cultures) and say it’s the only way to really learn those skills.

Gabrielle milked a couple of hundred goats in Western Australia following biodynamic farming principles and her cheeses won her Australia’s top cheese-making award in the late 1990s. That led to her being invited to judge cheese in France which exposed her to the multitude of cheeses on offer in a country with centuries of cheese making behind it.

‘I don’t want to see those traditional foods disappear completely and there’s a lot of awareness as well as a huge appreciation of them now. So we drag ourselves along to the local market where we are so stimulated by people’s appreciation.’

Thirteen years ago she visited family in Golden Bay and fell in the love with the region, returning two years later with Alan to put down roots in the totara-studded dairy pastures of East Takaka. It was part of her retirement plan where she would settle down to “have cups of coffee with friends and do all those civilised things”. Instead, she found the passion for producing traditional cheese could not be shelved so easily and when the law changed to allow raw milk cheese, it was just too irresistible.

“I don’t want to see those traditional foods disappear completely and there’s a lot of awareness as well as a huge appreciation of them now. So we drag ourselves along to the local market where we are so stimulated by people’s appreciation.”

Now, with retirement postponed indefinitely, they are often working long hours to create a range of cheeses in their tiny fromagerie which is tucked away in a converted farm shed and shipping container. They’ve built it from scratch themselves and that’s despite Alan being legally blind from a caustic soda accident in a cheese factory many years ago.

The decision to create their own cheese was helped along by the fact the dairy farmers over the fence had a similar philosophy as their own about soil, pasture and animals which enabled them to source fresh milk to make cheese like the cheese makers of old. In the early hours of the morning, Alan heads to the farm’s dairy to grab the milk from the strongest cows at the front of the herd which will have the best quality milk.

“I wouldn’t have started without having the quality of milk,” Gabrielle says. “We’re really blessed to have that next door. And the fact we think milk shouldn’t be transported or shaken about and should be worked with in a very short period of time.”

While Gabrielle says she is still inclined to work with her nose and instinct when it comes to making cheese, Alan is the technical one. Though even with a degree in dairy processing and a diploma in dairy technology, he says it’s the anecdotes from those master cheese makers that built his knowledge.

Alan’s history in milk products began when he moved to South Africa as a 17-year-old and worked in a large dairy that was a far cry from today’s sterile environment. Starter cultures were incubated in the sun on the roof and product was made in basic buildings without doors. He remembers being fascinated by an old timer whose sole job was to take a ladle of milk from each can delivered to the factory and decide whether it was acceptable or not.

Even though the factory had its laboratory, Alan says the old timers experience and accuracy was still the best judge of the milk. Despite the basic set up of the factory, it worked because the people knew how to work with the natural bacteria. When the dairy moved to a modern factory and became the first factory in South Africa to process a million litres of milk a day, those original starter cultures died off and the amasi – fermented milk – never achieved the same taste.

Today he is passionate about nature’s bacteria – the good and those that society now condemns as ‘bad’ bacteria which he says are all essential to achieve balance. Nature has them there for a reason, he says, such as the E.coli and birth bacteria on a cow’s udder that is essential for newborn calves to digest into their gut when they have their first drinks from a cow, or the young children that are exposed to a wide mix of bacteria to help build immunity.

“I know raw milk has bacteria and that comes from a cow – cheese-making cultures have all originated from the animal and the animal’s environment. This whole thing about cleaning everything up and being sterile means we’ve knocked nature on the head. In nature, it’s found its balance.

“It’s a war zone inside milk and knowing that, I know from the moment it’s in my bucket to being in the cheese vat, all I need to do is encourage the good bacteria.”

Around the globe, there’s just a fraction of the starter cultures for cheese that once existed. Alan estimates there’s only about 30 used now compared with more than 200 that used the moulds, yeasts and bacteria in nature to make cheese. He still starts his own culture, which is a rarity in today’s cheese industry, mixing and matching bacteria to get the different flavour profiles.

Flavour and quality of cheese depends on the milk too, such as different times of the season, which is why they don’t take the early season milk just after calving when it has “some really weird flavours” that aren’t suitable to make cheese using traditional methods. They wait until the middle of September before beginning their cheese making season, with hard cheese even later. It limits them to making cheese for about six months of the year, but they’re passionate about the authenticity of their creations.

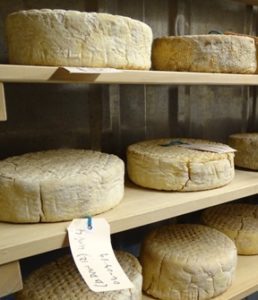

Some of those creations bear the names Innocence, Knowledge and Wisdom in the hard cheese which are matured between two and 12 months. They originate from the rootstock of all hard cheese and date back to pre-Roman times in Europe without a trace of modern bacteria.

That was going to be the extent of their cheese making – hard cheese with varying maturities. Then a hard cheese with a “blush of a wet rind” followed which combined soft, modern European cheese with hard traditional cheese. When customers in Golden Bay began asking about camembert-type cheese, they created a white rind cheese around acidic creamy curd without the usual gooey centre and called it Essence. That led to their most popular cheese yet, Love, with its thick rind encasing a creamy centre, which has been followed by a semi-soft blue with the mould growing naturally through it instead of the modern way of inserting it with needles. More recently is a white sour cream cheese sold in a plant-based bag. It was created for one of the bay’s iconic cafes, The Mussel Inn, which uses it on top of their nachos and now locals are using it as an alternative to sour cream, but without the additives.

It’s still very much a fledgling business and even though it has grown to a stage they need to employ a couple of part timers, it’s not yet big enough to reap an income. Creating even a small cheese – especially raw milk cheese – fromagerie takes time, effort and quite a bit of money. Simply placing a shipping container on an established concrete site required a $3,000 bill from a geotechnic engineer to say it passed earthquake requirements. The consents for each part of the business, which fortunately was finally considered cottage industry rather than industrial, was long and expensive.

“They wanted a fancy elaborate thing for the whey, but we were just feeding it to the animals,” Alan explains. “When it came to food protocol, we built all the equipment ourselves which had to be verified by a verification engineer and that was $3000 just to get him there. Then two sets of audits. In total our compliance and costs were in excess of $30,000 and all we were going to produce was one batch a week from 100 litres – that was the minimum we had to do for compliance, whether it was in a container or 50sq m dairy factory.

“It was costing us about $6000 a year for two audits – one for the farm and one for us, even though the farm was already being audited by Fonterra.”

Then one day Minister for Agriculture, Damien O’Connor, turned up at their fromagerie and that led to the introduction of a remote verification tool which is aimed at reducing the costs for small food businesses around the country, especially those in rural communities.

It’s a start, Alan says. Better than before because they no longer need to pay for approved food safety verifiers to travel to their location and check facilities. Instead, they can use a smartphone or other device to look through the facility and talk through safety issues. It’s still got a wee way to go though and they will continue to lobby for cheese makers to have a minimum standard. Within the code of practice for all cheese makers, Alan says it talks about the owner/manager/operator being a person competent to do that job.

“But what does competency mean? It’s saying the responsibility is on the competent person, but I’m asking where is that competency measured? Nobody wants to answer that one.”

Competency is about understanding the environment and he says it’s not about absolute hygiene, but rather the experience gained by working in the industry, preferably as apprentices working with experienced cheese makers.

“Then we will have more dedicated cheese makers and people doing it for the love of making cheese with the competency that comes with that. Also you will have cheese makers who have learned at the foot of someone else and now take that method and put their own stamp on it.

“We’ve got to make unique cheese for New Zealand. We’ve seen the error of big cheese factories coming to a stop or a slow-down and we need variety. I think the best thing we can do in New Zealand is have small cheese factories making unique products.

“We still have our industrial market and overseas cheese, but every town should have a good cheese maker that’s producing a cheese that is unique to that region and not copying the bloke across the road or vying for place anywhere else. We get so many tourists that come to Golden Bay who say they have been all over the country and there’s cheese everywhere but we haven’t tasted anything like this. That’s what gets us out of bed every morning.”

Alan says smallholdings producing their own milk and making it into cheese, or dairy farmers who want to add another dimension to their business by making cheese for their community can have a viable business.

“I think people will support local in small communities.”

It’s a vision that has prompted them to look at the costs of helping others set up fromageries and gaining the skills to produce local cheeses. For $150,000, Alan says they could build micro fromageries themselves in Golden Bay and deliver them to budding cheese makers around New Zealand, with the Risk Management Programme completed.

That would enable those cheese makers to start making their own cheese once they had a food safety programme, or they could learn how to make cheese under the guidance of Gabrielle and Alan, then produce and sell cheese under licence. Buying a licence would provide them pre-mixed cultures and the training for the different cheese varieties, with a royalty paid on each variety, until they reach the stage they are confident to go out on their own and produce their own unique cheese.

“What we’re doing is making cheese that doesn’t taste like other cheese and doesn’t smell like other cheese. And you can only do that from starting small and teaching your immediate market what cheese really is.”