Team effort

The team at Poplar Partnership in southern Manawatu have taken out the region’s Supreme environmental award with a combination of focusing on people, livestock, land and biodiversity.

Report: Jackie Harrigan. Pictures: Brad Hanson.

Building an intergenerational family dairy business, focusing on efficient cows, developing numerous properties, and sustaining a snail reserve requires a wide skill set. Their combined talents and work ethic earned the McErlean whanau from Poplar Pastures at Moutoa, southern Manawatu, the supreme award in the 2023 Ballance Farm Environment Awards for the Horizons region.

The judges said they were impressed by the family’s commitment to people, livestock, land stewardship, biodiversity and habitat creation resulting in a highly successful and sustainable business.

The Poplar Pastures team – and a large number of the team walked on stage at the awards to pick up the Supreme prize, – also won the Ballance Agri-Nutrients Soil Management award, Bayleys People in Primary Sector Award, DairyNZ Sustainability and Stewardship Award, Hill Laboratories Agri-Science Award, Norwood Farming Efficiency Award and Rabobank Agribusiness Management Award, before taking out the Regional Supreme Winner Award.

Poplar Partnership

The McErlean family has been in the Moutoa area since 1939 when John and Peter’s grandfather bought 87 acres (35 hectares) and brought a small herd of cows from Whanganui. The farm was taken over by their father in 1963 and expanded to 165 acres and later bought by Peter in 1995.

John and Karen purchased and converted 107 acres across the road in 1983 and over the following 18 years bought and joined up surrounding parcels of land. John and Karen joined with Peter to form Poplar Partnerships in 2002 with the three of them directors. The partnership has 3030 shares, 3000 with no voting rights (owned by Peter, and John and Karen’s trusts) and they each individually own 10 shares with voting rights.

Most of the land (2000 ha in total) is leased off the directors’ trusts by Poplar Partnership as well as KopCreek (owned by John, Karen and Peter individually) and Next to Nature (owned by the family’s trusts 50% and 50% by YPF, the trading company of the Lake Road farm contract milker Yhan Franks).

Since 2002 they have developed the Poplar Road farm to milk 2200 cows, the Lake Road farm contract milked by Yhan is milking 550 cows and the small farm 164 Partnership winter milking 200 cows. Twenty years ago they built a large 80-bail rotary milking shed and feedpad complex and have added calf rearing sheds and workshops and machinery sheds. The partnership employs 30 team members, including a number of the next generation, two of Karen and John’s children and a number of nephews and grandchildren. Providing opportunities for local people is one of the family’s guiding value principles, and both John and Karen say it’s great to be able to provide opportunities for locals from their two local towns, Foxton and Shannon. Both John and Peter have been involved in the local rugby club, and find that a great source of potential workers, as well as local women who are in the milk harvesting team and students from nearby Massey University.

Karen manages the milk harvesting team, calf rearing, labour and administration. Her daughter Cara, who is a vet nurse, is also involved in admin and calf rearing, animal health and breeding. She does all of the cow administration and recording.

Karen says responsibility for teams is under each director’s area of expertise and the teams are on different rosters, but she coordinates the rosters and staff are able to swap rosters but need to let her know. Peter is director of the Poplar Road dairy operation. John and Karen’s son David manages the rotary shed and oversees the 2IC herd manager and the three trainee herd managers whom Peter is teaching the art and science of pasture management.

“While we run a system 4 operation, we are really good at pasture management which is our main advantage – pastures are the main thing for us.”

His motto is “every grazing at the right level on every day on every block.”

“I have been using the same system since we had 120 cows and I do it by sight and nail every grazing and clean out every paddock.”

Stocking rate has been reduced

from four cows/ha to 3.1 cows/ha at Poplar Road and Peter says topping is a cost and if a paddock isn’t cleaned out it might as well go into the silage stack.

“I take out a larger area of silage than I think we will need – if you can’t control and harvest the feed then the costs grow.”

John McErlean, who says he has just got the Gold Card, added that he won’t be retiring any time soon.

“I don’t want to retire, I will just potter along and see where we go – I haven’t been in the cow shed for years and I am not going back there.”

He is in charge of feed/supplements, R&M, the contracting employees, the beef operation and beef breeding. He oversees all development and maintenance, the digger driver and full workshop team who do all of the maintenance on the full complement of farm and contracting equipment and also are training an apprentice mechanic.

John has long been keen on development, but only in the appropriate place. He is also a keen environmentalist and has developed 15 wetland areas across all of the properties, incorporating many duck ponds on the 300ha heifer runoff block, fencing off and planting 1500 natives each year with help from Horizons and taking on the responsibility of two native snail reserves, totalling 3ha, home to the endangered giant Powelliphanta snails, a species of giant carnivorous land snails that eat native worms and slugs.

The duck-shooting lakes are now established with plantings and maimais and there is a pecking order of who gets to shoot which pond – with John having the best spot.

“Of course, it’s cost me about $200 a duck, but it’s a lot of fun,” he laughs.

Retaining and growing staff

Staff are generally very loyal to the Poplar Pastures business and appreciate the family atmosphere, working alongside the directors.

“It’s a seven-day a week business and when the work needs to be done we are all in, and work long hours, but on a wet afternoon people are able to take the time off if they are not needed.”

But team members were always subject to attractive offers from alternative employers and when John and Karen and Peter were wondering how to encourage them to stay in their business they started to think laterally.

“You have to put yourself in the employee’s position and think about what they might want,” John says.

“Most workers on a dairy farm are never going to be able to own their own farm.”

So, when a small farm next door to the Lake Road farm came up for sale six years ago, the McErleans formed a partnership called 164 Partnership and asked their long serving staff to partner with them in the venture.

The three McErlean directors owned three shares and Poplar Partnership Ltd guaranteed loans for the other five partners, all of whom purchased a 12.5% share in the operation (farm, cows and machinery). Each partner borrowed up to $500,000 for their share, and the interest payments were covered by the farm.

Yhan Franks, the Lake Road farm contract milker was one of the shareholders and took on the contract milking of the 200-cow winter milking property.

“Six years into the venture, it’s been a great experience to be able to have an ownership share and a great way of building an asset. Rather than being paid a bonus – which may have been easy to spend on something inconsequential, the farm has paid a lump sum to each partner for the past four seasons (of up to 6.2% ROI last season) and partners have been able to pay down their debt and be part of yearly meetings on strategy and planning.”

Three years ago, all three McErleans sold their shares and three other employees came into the partnership.

“The only rules are that if they leave, they have to take out their share and someone else gets a turn,” Karen says.

“But it’s a good way for them to get an idea of what’s involved in ownership and a great way to build an asset and get exposure to banks and accountants along with opening their eyes to the costs and compliance involved in the dairy industry.”

Irrigation and drainage

The Poplar Road farm incorporates leased land on the Moutoa Floodway which can be subjected to three floods a season and while it is high risk there are high rewards.

Fertility is lower over on the floodway so it tends to be used as night paddocks to capture more nutrients, while some of the Class II land on the Shannon side of the farm is former horticultural land sporting Olsen P levels of up to 50.

“The class II land doesn’t need much fertiliser and so we think hard about where to put our fert dollars and have done comprehensive soil testing to help make those decisions.”

The family has a strong cost control ethos so controlling costs in the biggest blowout areas of feed supplement, fertiliser and wages along with rising interest rates is important.

“We harvest and use our own maize and grass silage and fed PKE and DGG last year with the high payout, but I’m not keen to put as much (supplement) in this season to buy production,” John says.

Irrigation was added three years ago (and John says they haven’t made any money from it yet as it’s been wet ever since) after they decided to make the most of a water consent bought with the last block of land.

But 300ha of the land is tile drained into big drains and gates have been installed in the drains that hold and recycle the irrigation water pumped from the river and therefore recycle the nutrients in the system. The effect is to hold the water table higher as well as mitigate in times of low river flow when the consent is halted, and irrigation can continue, by pumping from the drains.

“In a dry summer, no water leaves the farm – except in the milk.”

Monitoring on the loss and recycling of nutrients is about to begin by Massey University as part of their Edge of Field nutrient loss mitigation research.

In pursuit of the efficient cow

Cara How has taken on the breeding programme at Poplar Partnership and says it is really important to breed cows that are as efficient as possible at converting feed to milk.

All yearlings are mated by AI with Friesian semen and five of the best heifers cycling each day (that are not contracted to LIC) are mated with sexed semen to select heifer calves for replacements.

All of the above-average BW cows are mated to Friesian semen and below-average BW cows are mated to their own Hereford straws for beef cross animals. (Average BW: 212 and PW: 265). Cara says she is on MINDA Live every day and uses Protrack to draft out cows.

“Each year we are getting good improvements to our averages as our replacements are out of the best animals,” Cara says.

The family rear 700-800 replacement calves and some beef calves, the rest of the Friesian bull calves and beef calves are all sold to repeat buyers. At the end of the season 120 white-faced beef heifer calves are reared for the embryo programme. Last season they implanted 150 embryos from 12 cows. LIC have contract matings in the herd also – cows, yearlings and in-calf heifers. A work-on this season for Cara is the Not-In-Calf rate, usually 14% in cows and 7% in heifers; was 19% for the cow herd this year and 12% for the heifers. Between 100-200 carryover cows are milked through the winter along with the 600 autumn-calving cows and the late spring calving cows (cows calving in September and October are not dried off until July 15.)

Dry cows are wintered on the runoff and fed maize to lift their BCS by 0.5 a score. They then calve at the runoff and are trucked home, which cuts the rate of milk fever as they stay on the same feed during the buildup to calving.

Heifers are all milked OAD for their first season because of the 3km walk to the shed and this has kept their condition on and reduced lameness to 5%.

Each of the five herds is brought in to milking individually, they are not followed and are able to take their time coming up to the shed before milking for feeding on the feedpad. And lame cows are milked through the herringbone shed and rested close to the shed. Work on the races is ongoing.

Milk from the A2 cows milked through the winter is contracted by Fonterra for liquid milk for supermarkets. The farm has never had a penicillin grade through their main rotary shed – because there are no drugs there, Cara says.

Every cow is stripped each morning and is transferred to the 40-aside herringbone shed if it needs treating. Paul McErlean runs that shed and anything that is being treated goes through here – colostrums, mastitis cows, lame cows – and they are all milked once a day in the morning and transferred back to the main shed when they are cured.

Farm Detail:

Farm Detail:

Total area: 1719ha Poplar Partnership; dairy platforms 693ha eff Poplar Road, 237ha Lake Road, 97ha 164 Partnership.

Topography: flat (dairy platform) 2.5m asl, terraced dunes and flats (runoff)

Annual rainfall: 1000mm/year

Soil types: silt and sand (dairy platform), sand on runoffs, Kiwitea loam/silt/peat (Koputaroa runoff)

Cows: 2200 cows on Poplar Road (3.1cows/ha, ) 550 cows at Lake Road (2.3 cows/ha)

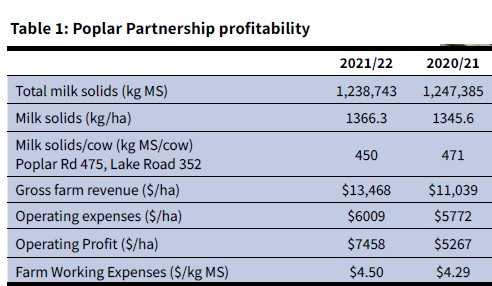

Total kg MS: 1,045,082kg MS Poplar Road (1508kg MS/ha, 475kg MS/cow)

193,661kg MS Lake Road, (817kg MS/ha, 352kg MS/cow)

Total feed eaten: 17.5t DM/ha

Enteric methane: 9.5t CO2-e/ha

Farm system: Poplar road system 4, Lake road System 2.

Points of difference:

Supply A2 liquid milk to Fonterra

80 purebred Hereford beef breeding cows to breed their own bulls to tail the herd plus take semen off for their own use.

Embryo transplanting and bull breeding for LIC/CRV, about 30-40 contracts/year.

Do all their own contracting/harvesting – including maize, hay and grass silage.

John has created or extended multiple (14-15) wetlands and native plantings for many years

164 Partnership – a small 200-cow winter milk dairy farm owned by the McErleans and eight key staff members set up for staff retention.

Own servicing workshop/mechanic also complete outside work when time is available.