Jackie Harrigan

Jonathon and Linda Sievwright are using less than half the freshwater of a typical dairyfarm, thanks to a greenwash and effluent system designed by local engineers and built for their Manawatu dairy farm conversion seven years ago.

When they converted their 100-hectrare heifer grazing block to carry and milk 230 cows, the pair looked around for a simple but effective system that would help them to conserve water on the System three property.

The system means they use a very efficient 30 litres/cow/day of freshwater for the shed and yard, compared with 70l/cow/day for most dairy farms.

The presence of the Waituna West water scheme made their conversion possible and as luck would have it the scheme was being upgraded with a new plentiful bore at the same time as the Sievwrights converted, so they secured 14 units (one unit = 1000 litres), which was boosted to 30 units when they bought a neighbouring property.

The 28-bail rotary shed at the Waituna West property and adjoining yard with greenwash on the backing gate, drains greenwater to the effluent pond through a weeping wall, a simple system planned by the Sievwrights and Horizons Regional Council’s environmental consultant Logan Bowler. The green water is recycled to wash the yard, flowing out of nozzles on the backing gate and green water also pumped from the pond and applied through a Greenback spider travelling irrigator on to the 30ha effluent area.

Local contractors, Paul Roberts from Rural Building and Engineering and Steve Bromley from Bromley Dairy and Pumps brought all the plans to fruition and the system has worked without missing a beat for the past seven years.

The timber fixed under the backing gate flattens out and breaks up the solids and the green wash coming out of the nine nozzles is under enough pressure to move the solids in two rotations of the gate, which takes around eight minutes twice each day.

The system is operated with a remote control, easy for one of the milkers to turn the gate and pump on and off.

Across a 280-day lactation, including 90 days of OAD, the Sievwrights say they save lots of water, which creates a lot less effluent.

They installed a one million litre capacity pond, which far exceeds the requirement for 90 days’ storage in the Horizons region.

“We built it to future-proof the property with the thought that we or the next owners might like to expand to 300 cows – the pond never gets full unless we have heaps of rain – and then we can divert the stormwater off the shed roof and the yard so that cuts down the clean water into the pond.”

The dry solids from the weeping wall are cleaned out by a contractor and applied to the pasture three times each year.

“It gets spread out on to paddocks with the contractor’s ‘flinger-dinger’ – that’s what we call it,” Linda says.

“It doesn’t smell or go slimy, it’s quite dry by the time all of the liquid has oozed through the wooden-slatted wall.”

The Sievwrights have been fertilising the effluent area slightly differently to the rest of the platform where they apply 30% potassic super at 400-500kg/ha split into autumn and winter dressings. The effluent area has straight super. Jonathon, who has retired from milking and does all the outside jobs, dresses the farm with urea following around after the cows – applying 160kg/ha/year.

“We knew the effluent was concentrated but we have only been applying a small amount.”

The greenwater monitoring results show they were right to cut out potassium on the affluent area, to avoid overdressing.

Greenwash research

Logan Bowler, who now runs his Agblutions Consultancy from his Rangitikei farm and Bob Longhurst from AgResearch Hamilton, presented research to the recent Farmed Landscapes Research Centre Conference (formerly Fertiliser and Lime Research Centre) on using greenwash water for yard washing based on the Sievwrights’ operation.

“When I went to find some research about the use of greenwash, I found there was nothing out there, so we did it ourselves,” Bowler says.

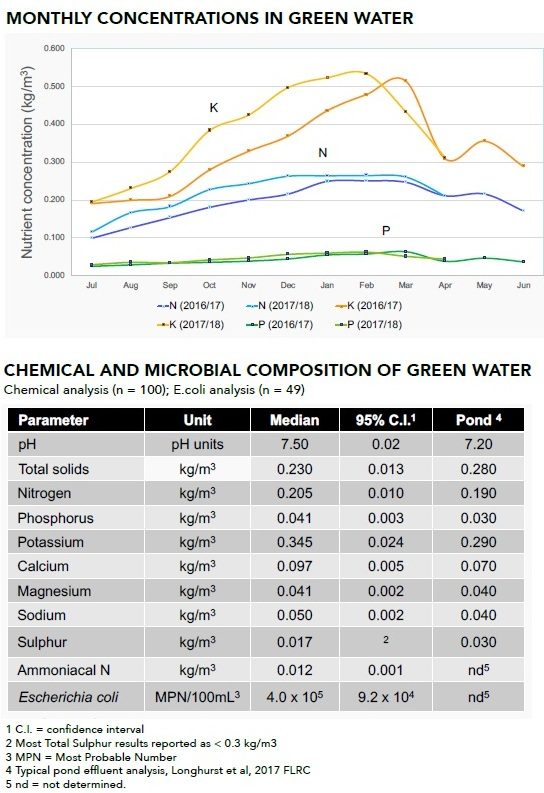

Their approach was to measure water volumes and to characterize the chemical and microbial composition of the greenwash (unstirred pond effluent), at the point of entry onto the yard over a two-year period.

Bowler and Longhurst found incorporating the greenwash into the backing gate is the most efficient method to apply greenwash and options include; using 4-5 nozzles and a drag chain to break up the dung pats, using a number of small jets with a scraper on the backing gate and using a floodwash system.

Bowler is a keen proponent of greenwash systems, saying clean water is a valuable natural resource that can no longer be taken for granted.

Dairy farms require 70l/cow/day for stock water and are currently using 70l/cow/day for dairy shed use but water used for cleaning the holding yards doesn’t have to be of the highest quality and recycling pond effluent is a great way of reducing water abstraction and lowering farm working expenses – with savings in labour, pumping and water extraction, he says.

Case study findings:

- Dairy shed water usage averaged 30l/cow/day, compared with industry standard 70l/cow/day (DairyNZ research)

- Water savings 3000l/day, time savings 20 minutes/day

- Overall nutrient concentrations were slightly higher than typical pond effluent

- Green water is more K (potassium) rich than typical pond effluent

- E coli levels were within typical range found for pond effluent

Industry rules for using greenwater:

- Green water must be free from sediment and solids

- Can only be applied at low pressure to avoid aerosols (and reduce pathogen risk)

- Can be applied no higher than 300mm from yard surface

- Must not be used within 5m of any milk harvesting equipment

- Can not be used when cows are on the yard

Conclusions:

- Major water savings achieved, with flow on effects for less time needed for cleaning the yard and spreading reduced volumes of effluent to land.

- Effluent pond storage requirements are greatly reduced.

- Application to land should be governed by meeting pasture K requirements.

- Green water systems are relatively easy to install.

Farm facts

- Jonathon and Linda Sievwright, Waituna West, Manawatu

- 100ha platform

- 230 Kiwicross cows

- 100,000kg MS, 434kg MS/cow

- System 3-4

- 28-bail rotary, in-shed feeding