While it’s possible to show that dilution from extra milk production can result in a farm having low farm operating costs despite high feed costs, there aren’t many who can achieve it in practice, farm consultant Jeremy Savage says.

The Macfarlane Rural Business dairy consultant is contracted to the Lincoln University Dairy Farm as a consultant and management team leader

He says analysis of client financial data including LUDF shows that for every $1/ kg milksolids (MS) increase in feed and grazing costs there’s an extra 51c/kg MS lift in operating expenses – a similar number to come out of DairyBase analysis of national and regional farm data.

Jeremy says it can be difficult to pin down exactly where the extra 51c/kg MS operating costs comes from.

They’re often termed hidden costs and are likely to come from additional vehicle costs associated with feeding, increased running of tractors, higher servicing costs, extra fuel, maintenance and repairs of feed out wagons and feed mills, he says.

Autumn feeding of supplements can increase pasture damage particularly when silage is fed out in the paddock.

Track wear and tear is increased, lame cow numbers can increase and cow condition can be affected.

A good quality feed costs 40c/kg drymatter (DM). It takes 10kg DM to make 1kg MS. In theory this should cost us $4.00 to make 1kg MS. With the extra costs associated with feeding, the real cost appears to be $6.08/kg MS.

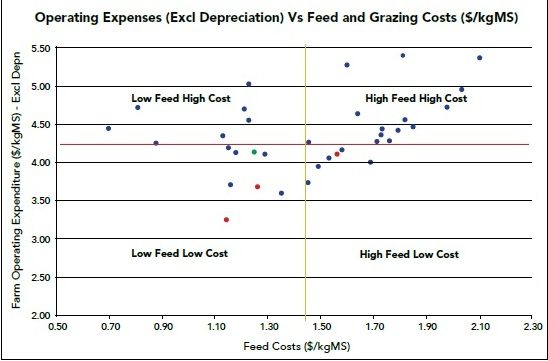

When feed costs are graphed against operating expenses the resulting data from farm clients can be divided into four quadrants.

The low-feed-costs, low-operating-cost farmers are typically his most profitable clients.

“They have simple, easy-to-replicate systems. Per-cow production is not always compromised but is often slightly lower due to management factors such as earlier culling.”

The number of clients who can operate in the low-farm-operating-costs, high-feed-cost quadrant is limited.

“They’re typically owner operators, including equity partners and are achieving pretty high per-cow production – 480kg MS plus per cow.”

Often those with high feed costs think high production will give them a dilution effect and a low total cost per kg MS.

“Unfortunately for most this is not the case; the execution is not there.”

If in the high-operating-cost, low-feed-cost quadrant it’s important to confirm what’s driving that.

For some it is irrigation charges or high cost of running support blocks but high repair costs for irrigation can blow this out too as can the effect of drought.

Farmers need to look closely at stocking rate and asses the effect of carrying a proportion of cows purely on supplement.

He cited the example of a farm where summer intake was 19.6kg DM/cow/day with the stocking rate supported by 2kg DM/cow/day of grain.

No silage was made and residuals were good.

“Based on the feeding levels at 2kg DM out of 19.6kg DM/cow/day 10.2% of cows were supported by the use of supplements – so 70 out of the 700-cow herd.”

On that farm grain was fed at 2kg DM all summer at 44c/kg DM but the response rate was high at 9.7kg DM to get 1kg MS.

The cost of feed in theory to make 1kg MS was $4.26 for those 70 cows.

But the additional cow costs need to be accounted for too.

Heifer value (25%) $150

Heifer grazing (25%) $245

Winter grazing $250

Animal health and breeding $174

Shed costs plus power $46

Labour (50%) $180

Total $1045

Milk production was 470kg MS so cow costs were $2.20/kg MS and added to the supplement cost to produce a kg milksolids of $4.26/kg MS the combined cost of supporting the higher stocking rate with continual use of supplement is $6.46/kg MS.

Jeremy says analysis of their clients suggests the actual cost of marginal milk may be as high as $8/kg MS.