Efficiency from amazing maize

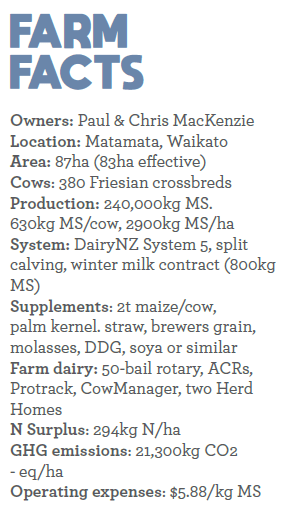

Waikato dairy farmer Paul MacKenzie is growing 43% of his milking platform in maize. Maize silage is an ideal component for his highly stocked winter milking system, but he told Sheryl Haitana there is always more efficiency to be found. Photos by Emma MaCarthy.

When Paul MacKenzie got the opportunity to purchase 47ha of land next door to his sharemilking job at Waharoa, he jumped at the opportunity.

He initially incorporated the land into the sharemilking operation, but when the sharemilking job finished he was left with 47ha and not so many options. After visiting a few different operations he decided he wanted to build a 50-bail rotary and two Herd Homes and milk intensively on the 47ha with the possibility of a 39ha lease block next door.

Surprisingly, the bank manager agreed. It was a relief to later be able to purchase the lease block during their five year lease period, otherwise he would have been left with that capital infrastructure and milking a lot of cows on 47ha.

Moving to a high input intensive system wasn’t always on the cards for Paul, but he quickly saw the benefit of feeding cows to their fullest potential. Within two years, production lifted from 340-400kg MS/cow to 500kg MS/cow.

“I couldn’t believe how quickly we got there.”

‘Maize is a great balancer to the volatile variability of grass. We feed it every day; it’s easy to

grow, easy to store, it’s very economical and it is a consistent feed.

The cows are now producing north of 600kg MS/cow with a diet of 40% pasture, 25% maize and the other 35% made up of complementary feeds including straw, palm kernel, brewers grain and molasses, distiller’s dried grains (DDG), soya or other sources of protein.

“Maize is a great balancer to the volatile variability of grass. We feed it every day; it’s easy to grow, easy to store, it’s very economical and it is a consistent feed.

“Because we could grow maize cheap and a lot of it, we were able to put more maize into the diet and overall create a more cost-efficient higher quality diet.

“It was basically working out the maximum we could put in the diet to ensure

the herd performed at their best – I think we’re about there now.”

They fed potatoes for a number of years but had issues with cows suffering from rumen acidosis, the potential for sick cows was too high.

“You can undo a lot of savings in feed with one mistake.”

The efficiency of the cows and the fact they are producing 2900kg MS per hectare makes the farm highly profitable.

With the maize grown onfarm costing just 11c/kg DM, they are not as vulnerable to price hikes for a good chunk of their feed.

In the two consecutive low payout years of $4.40kg MS and $3.90kg MS, when farmers were cutting out feed and labour they chose to keep the system the same and add someone to the team, charged with driving costs out of the business.

This responsibility was given to their son Rhys, who joined the team on a casual basis of one day/week.

Rhys challenged and analysed every spend Paul wanted to make ensuring there was a return or saving behind every decision and quickly paid for himself. Apart from taking the Fonterra loan, they were able to cashflow their losses without adding any further debt.

Planting the milking platform in maize

When Paul initially started down the road of a high input system, he bought all his maize silage in, but got caught out one year when a contractor was unable to deliver.

To fill this gap he then found himself in the market, buying expensive feed. To reduce their exposure to this risk they planned to grow a small percentage of the maize needed (3ha) on the milking platform and watched for impact. With no negative impact the 3ha became 6ha, then 9ha, 12ha, 16ha, 21ha, 25ha and now sits at 36ha – 43% of the farm.

“We just kept doing a little more each year. I think we are probably near our maximum now.

“With the amount of feed we were buying, plus the ability to feed high levels of maize whenever during the season, it made sense to winter milk and collect a premium.

“This also works well with the maize growing. We control our spring growth by taking paddocks out for maize.

“The second half of the maize growing season, when summer/drought comes and grass can slow right down, maize with its deep roots and high water use efficiency, continues to grow. Also at the same time when grass growth is diminishing, the farms demand for grass drops as cows are dried off for autumn calving.”

Paul used to rotate the maize around the farm, but now has a designated area of the farm which is drier, where they can plant the maize earlier, get it off earlier and get the annuals planted and growing, ready for the autumn calvers.

“We have had as many as four grazings before June 1 on the annuals.”

They grow 6-7t drymatter/ha of annuals between maize crops. The last three years Paul has been trialling oats (double cropping), trying to further optimise drymatter grown/ ha.

The flat Waharoa farm is vulnerable to wind and drought, so they grew Pioneer’s P0362 hybrid last year, which averaged a yield of 21- 22t.

“Growing maize on the milking platform works exceptionally well for us, otherwise we would be milking more cows. Instead, the maize crop mines nutrients and reduces our environmental footprint.

“The cheapest way to harvest grass is with cows’ mouths. We made grass silage one year (prior to growing maize on farm), added it to the mixer wagon, it wasn’t perfect, the cows left some of it behind in the feed bins, cleaning it up was just another job.

“Our goal is to only put feed in the feed bins that we can guarantee the cows will lick clean.”

Paul was always reluctant to get into high input farming, because his first impressions were that the systems were labour intensive and typically owner operated where owners were tied to their farms.

With this in mind when he set out he was determined to build a simple system which could be run with minimal staff, which he has achieved.

Paul and Chris employ a contract milker, who employs a 2IC and each of these covers the others weekends off, annual holidays and leave.

Herd homes

All of the infrastructure is well set out to make the daily operation seamless. The Herd Homes are able to double as effluent storage from the farm dairy as well and the effluent from the Herd Homes is spread over the maize paddocks, prior to planting and when the maize comes off, which works well.

Paul surrounds himself with top rural professionals, including nutritionist Sue Macky and Pioneer’s Ian Williams to keep analysing the system and improve efficiency.

“I don’t care how good it gets – there is always more efficiency to be found,” Paul says.

“I rely a lot on my rural professionals, and credits a lot of our success to them – bankers, accountants, farm advisors, technical reps and others.”

The big question over the farm operation now is the environmental footprint, with a nitrogen surplus of 294kg N/ha and GHG emissions figure of 21,300kg CO2 – eq/ha.

Paul is waiting to see where the dust settles with regulation before making any major system change. The numbers have changed significantly over the years as the Overseer model has continued to change.

Paul wants to see more consistency in the numbers and more research, incorporating milk urea numbers and ruminant nitrogen models. He believes the potential of maize to pull leaching out of the system also needs to be taken into account.

“Back when we were rotating our maize ground, we were annually soil testing every paddock and each time where the maize had been grown, fertility levels had dropped. Maize was definitely mining nutrients.”

The part of the farm with the highest N loss under Overseer is always the maize cropping paddocks, Pioneer’s Ian Williams says.

“This is despite the fact that the maize is known to take nutrients out of the soil rather than losing them through leaching,” Ian says.

“Every tonne of drymatter you take off with maize, you take off 12kg of nitrogen. So if you take off a 22t crop, you’re removing the equivalent of over half a tonne of urea.”

A Pioneer trial looking to measure N loss from maize silage/catch crop systems is showing the full capability of maize to reduce nitrogen leaching, Ian says.

Two-year results show that the nitrogen leaching loss is as low as 6-8 kgN/ha per year.

“There are a number of reasons for the low leaching losses. Maize produces high drymatter yields and therefore has a large nitrogen requirement. Its deep rooting structure allows it to take up nitrogen from depth. A winter catch crop utilises any excess N left over after the maize and reduces drainage by transpiring any excess soil water.”