Flexible milking frequencies have proved a solution to a Westport farm’s problems with dry summers, Anne Hardie reports.

Last season John and Jo Milne milked their cows twice a day, 3 in 2, 10 in 7 and once a day to achieve good production results during a severe drought on their Westport farm and plenty of sleep-ins.

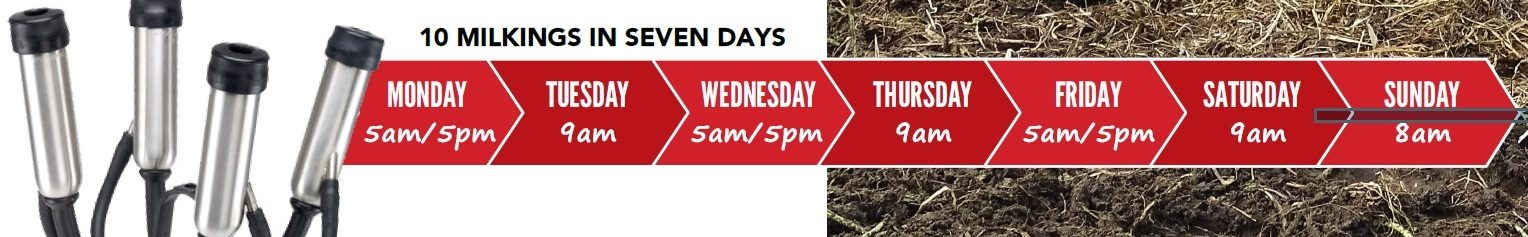

You read it right – 10 in 7. From mid-December to the end of February they were milking the cows 10 times during the week which meant twice a day (TAD) on Monday, Wednesday and Friday, then once a day (OAD) on the other days. And through the season they changed milking frequencies four times.

The cows took the changing milking frequencies in their stride, averaging 435kg milksolids (MS) per cow on unirrigated pastures that disappear in summer, by stretching the days in milk from the beginning of calving on July 25 through to drying off on June 10.

“By changing our milking regime around we could come out of the dry after summer with a larger number of cows still in milk for that autumn growth. It’s just what we have to do to make it work around here.”

‘The cows were always behind the mark; always struggling. We had older ryegrass and clover, 30-degree soil temperatures in summer and howling winds and out of all those things, it was only the pastures we could change.’

It’s been a gradual progression toward flexible milking frequencies in their quest to find solutions for the four months of summer dry on their Westport farm where they milk about 285 Jersey cows at the peak of the season.

It began years ago when they still farmed the Milne home farm north of Westport and bought a 127-hectare farm near Carters Beach on Cape Foulwind. The name says it all, as the hot summer winds blast the sand and pakihi-based soils which have been flipped in the past and soil temperatures can be as high as 30C. Pastures can’t survive and there’s no water for irrigation.

On the home farm with its river flats and damper summers, they milked twice a day (TAD) – “because that’s what we did”. But on the new farm, a tough year saw them struggling to feed the cows and get production and the following year it got worse. As a bird flies, the two farms are only kilometres apart, but the difference on the ground was dramatic.

“The cows were always behind the mark; always struggling. We had older ryegrass and clover, 30-degree soil temperatures in summer and howling winds and out of all those things, it was only the pastures we could change.”

They began buying in palm kernel and resowing up to 12% of the pasture each year, with a bit of rain around Christmas keeping it going. That was about seven years ago and since then, the summers have been getting progressively drier, though their annual rainfall remains about 2.2 metres. The cows were being fed better though with improved pastures and palm kernel, which meant higher production, but with higher costs.

At that stage they sold the home farm and moved to the Cape farm with their home herd which today has a BW of 135, PW 150 and 100% DNA-tested recorded ancestry. As expected, production increased and they were almost 400kg MS/cow – but production was coming off the cows’ backs.

“We couldn’t keep condition on them. By mid-December we were still doing over 2kg MS/day/cow but the grass was disappearing pretty quick and the cows were losing quite a bit of condition. So we went to 3 in 2 about mid-January and kept doing about 400kg MS/cow with less milkings.”

The 3 in 2 milkings have similar costs to TAD because, though fewer milkings, the cows take longer to milk and therefore use the same amount of power to chill the same amount of milk, but – and it’s a big but – you get a sleep-in every second morning. That was five years ago – and “got the neighbours talking”.

A cold, wet spring followed the next season and about October 25 they switched to once-a-day (OAD) for the rest of the year, achieving 405kg MS/cow and they were in better condition.

“But we didn’t get the sleep-ins!”

That was because the farm relies on a community water supply which means pressure drops off after the morning milkings in the district, so they still need to milk reasonably early.

The results got them thinking – what can these cows do? The herd had good genetics and the farm got a good spring and autumn flush of pasture growth, so they needed as many cows in milk as they could through summer to maximise that late-season growth. And they needed more days in milk. They had been calving August 10 and the dry summers were biting earlier and harder so they were drying the cows off about May 10. The season just wasn’t long enough.

They called in Farmwise consultant Brent Boyce who suggested they try 3 in 2 milkings during the week and OAD at weekends.

“We sat at the table with our jaws on the table – because that doesn’t happen.”

It did happen though and the wheels didn’t fall off, so last season they took it a step further and milked TAD every second day through the week and OAD during the weekend for 10 milkings in seven days. They achieved their best results yet at 435kg MS/cow and a total of 120,000kg MS, with cows in good condition through a hard summer and the joys of sleeping in a little later during the weekend.

“What we’re starting to understand now is the udder stimulation means you can change the gap around with the milkings. If you can get it purely from extra milkings on 3 in 2, we thought we’d give it a go. And it worked really well – as long as you did those night milkings around 5pm during the week.”

The season began with TAD milkings through to the last week in October when they switched to 3 in 2. By mid-November they had the last of the rain for the year and the farm began to dry out, prompting the switch to 10 in 7 milkings in mid-December which they continued through to February 20 when the summer crops were finished. From then on it was OAD milking and the dry continued through to April when the herd was able to make the most of the late autumn growth which was up to 40kg DM/day in May.

The Milnes employ one fulltime staff member who got a late start every second day during the week, though structuring work hours around changing milking times took a bit of thought.

“You’ve got to make dairying attractive because it’s a battle at the moment to get people. Our staff have every weekend off apart from calving.

“The best thing about it all was the cows want to be milked – you don’t have to force the cows to the shed. And they just get into the routine. I think the cows adjusted better than we did – your body clock is the biggest problem until you get used to it.”

He says it only took the cows three to four days to adjust to their different milking times and after that they just continued grazing when they didn’t have the extra milkings. Switching between TAD and OAD for the 10-in-7 caused no problems with somatic cell counts and they averaged a healthy 49,000 cell count through the year.

Whatever the milking frequency, the cows are fed the amount of feed for the time they will spend in the paddocks, so the days they are milked just OAD, they get the same amount of feed for the day they get on TAD milking days.

Through summer, that doesn’t include much grass because it’s gone – a victim of the wind and 30C soils. Summer crops of either chicory or rape provide the basis for the herd’s diet, with palm kernel topping them up at up to 4kg/cow/day if conditions get extreme, plus balage as a filler. Of the 119 effective hectares, the cows are milked on about 106ha, with the remainder in different stages of winter or summer crop, or regrassing. The latter has seen the pastures change to a ryegrass-clover mix on heavier soils, cocksfoot and clover on sand, plus fescue and clover as a summer

crop, with chicory and plantain in all those mixes.

It was a tough start for the summer crop of rape this year which was sown on October 1 and struck well with October rain but then struggled when the summer dry snuck in earlier than usual. Because of the dry, the herd started on the rape crop on January 1 and got to February 15 with it. Fodder beet was sown in early December and the cows went on to that crop at the start of April, with the mixed-aged cows then munching solely on fodder beet through winter.

The summer dry pushes their farm working expenses (FWE) up by 50-60c/kg to $4.02/kg MS. One of the benefits of the sandy, flipped ground is that it carries

the herd well through winter, with the frost-free climate enabling continued grass

growth to set the farm up for the early calving start on July 25. In the past, preflipping, the pakihi soils would have been pretty much a bog in winter.

Going forward, the Milnes want to identify a crop that harvests moisture from the soil through summer and one of the options to trial this year is maize which could be sown at the beginning of October and harvested to feed out to the cows. The problem will be wind which will probably flatten the outside rows, but John hopes the bulk of the crop can be harvested to feed to the cows from the beginning of January.

Longer, hotter summers are now creating another problem, with facial eczema. Even

without rain, a little dew in late summer can be enough to encourage fungus and this past season they estimate it affected about 25% of the herd, though John says it was only visible on about 7-8%. They now give the cows bolus capsules – twice one year – to prevent it.

“As soon as we see mushrooms in the paddock we know we’re in trouble. Spore counts can be low and then three days later they’re through the roof, so it’s tricky to pre-empt. It’s quite costly to give them the capsules but you know every animal gets one.”

Another challenge they have yet to solve, which is a result of their varied milking regimes, is fitting the cows into LIC’s artificial insemination (AI) run. One day the cycling cows are drafted at 7.30am after milking and the next day they are drafted out after the 9am milking when the cows will have to wait until midday to be inseminated.

But John says it’s the only downside of their flexible milking frequencies, with the positives being better hours and weekends, plus less pressure on the cows for similar production.

“If you can do less milkings for the same production, it’s something you have to look at.”

Farm facts

Owners: John and Jo Milne

Location: Cape Foulwind, Westport

Area: 119 effective hectares, milking on 106ha

Cows: 285 Jersey cows at peak

Production: 120,000kg MS; 420kg MS/cow

Milking frequency: Twice a day, 3-in-2, 10-in-7 and OAD through season