Focus on the leadership

Jonathon & Stacey Hoets - Canterbury/North Otago Share Farmers of the Year. By Anne Lee.

It’s been a big season for Jonathon and Stacey Hoets – realising their goal of farm ownership with their 20% equity stake in a 760- cow farm, Kairoa Dairies Ltd, and now winning the Canterbury/North Otago Share Farmer of the Year Award.

Kairoa Dairies is part of Rylib Group, a family-owned business in Mid Canterbury, which has people, culture and performance at the heart of their values – something Jonathon and Stacey align closely with.

Jonathon doesn’t leave a lot to chance. Long-term visions and planning are a key characteristic of the couple’s progression story.

“I like to think about where I want to be in five years, work out what skills I’ll need and start building up my knowledge so when that five-year period comes around, I’m ready for it.”

Earlier in his career that meant upskilling in farm management well before he had a manager’s role, then attending courses on business management and progression.

As their equity partnership goals came closer to fruition and as they had a family, Jonathon says his thinking turned towards industry roles that meant he could have a greater influence over the future – both for his family and the industry.

That’s meant his sights have been on developing governance and leadership skills.

He’s completed a Mayfield Group governance course and says that not only developed his skills it also allowed him to mix with others with similar goals and network with skilled and experienced governors presenting at the course.

Jonathon says he’s been well supported too by the couple’s equity partners John and Kelly Nicholls, who are both experienced in business and John experienced in industry governance.

“If you want to be involved in governance it’s important to start talking with people who are already there, get to understand different points of view and learn about good risk management.”

Jonathon spent his early years on a dairy farm in the Waitaki Valley but moved to Christchurch after his parents sold the farm.

“I always knew I wanted to go farming and worked on farms during the holidays while I was at St Bede’s high school.”

He went straight to dairying from school, progressing through the ranks, and then going contract milking with his brothers for a year before taking on farm manager roles.

“I love the competitive nature of Canterbury and striving to be in the top 5%.”

Just over 10 years ago he and Stacey set a 10-year goal of being farm owners.

“We were very open about our goals with John and Kelly five years ago when we looked at the job here at Rylib Group, so we came up with a plan, gave it a couple of seasons to ensure both parties were happy with where we were heading, and this season we became equity partners.”

Stacey, a psychology graduate from Otago University, was the swim school manager at the EA Networks centre in Ashburton before the couple had children.

While she’s not working on the farm day to day, she’s a sounding board for what’s happening onfarm and actively involved in the decisions for their own business.

“We make decisions that not only grow Kairoa Dairies but also grow and benefit the Group as a whole,” she says.

Stacey shares Jonathon’s views on managing people and teams.

Creating great workplaces for people is high on the priority list with family values a big driver and health and safety woven into the fabric of the operation.

“Rylib Group has a great culture and system in place to allow us to build on these values,” she says.

“We’re very focused on health and safety, it’s very much part of the team culture within the group. It’s part of everyday and every decision,” Jonathan says.

“We’re family people and the focus is on wellbeing.

“It’s important to us that everyone gets home safe and well and in time to be part of family activities.”

That means being flexible to ensure people can get to events that are important to them, having enough people in the team to allow jobs to be completed in a timely way and that they’re trained and well-resourced to perform at a high level.”

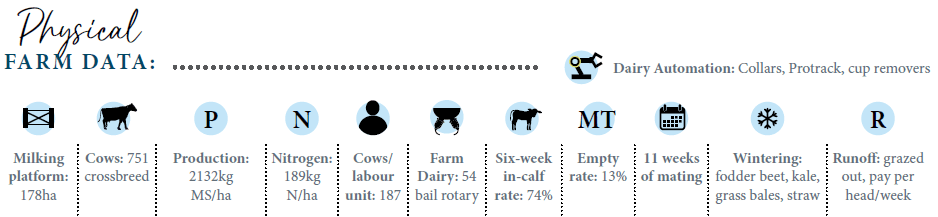

Maximising high-quality pasture intakes is also a big priority on the farm.

They have clear and well-executed processes for measuring and monitoring pasture growth and pre- and post-grazing residuals.

Setting up for next season starts in the late summer/autumn of the previous season with round lengths increased to ensure average pasture cover targets are achieved at dry-off.

The first early culling is carried out in December when any problem cows in the bottom 1% for production, based on herd test, are sent away.

Another early culling round can take place in January with the rest leaving based on a planned culling schedule from March through to the end of April. The farm is walked weekly to monitor pasture covers and pre- and post-grazing covers checked daily.

Round length starts to be pushed out in late January so it’s at 28-30 days in February, heading towards 35 days by the end of March/April.

Cows are dried off in mobs according to condition score.

They start out on kale and then move on to fodder beet before returning to kale before calving.

The wintering block is across the road so mobs can be moved back according to calving date, going on to a grass springer paddock that’s been pasture-sampled in late June so there’s an accurate assessment of additional minerals needed for a balanced springer diet.

“We do a lot of back fencing through the spring to protect the soils and pastures and to ensure good animal welfare outcomes.”

This season all of the cows are fitted with Allflex collars.

“We had half of them with collars last winter and it gave us some indication of animal health in the herd but we’ll have more information this winter and it’s going to be interesting monitoring them especially over transition.

Jonathon says the proximity of the wintering block to the milking platform means they can run mobs back through the farm dairy and use Protrack to auto draft into new mobs if required. The collars were used for this season’s mating with information on cow heats coming through right from the first heats post-calving.

“We used to do six-week, pre-mating heats with tail paint and it would mean either me or the 2IC in the stand. “We went to a camera but we’d still be in the stand for mating.

“This year all the pre-mating heat information was there automatically from the collars and we did use it for a group of cows we CIDRed.

“I did get up on the vet stand for three or four days at the start of mating but after that we left it to the collars.

“Our six-week, in-calf rate has gone from 74% to 78% and our empty rate is 9% down from 13% after 11 weeks’ mating.

“We usually do a final scan in May but we’ll use the collars for that this year.”

Jonathon’s very open to technology, backed by science, that brings multiple benefits. The farm has variable-rate technology fitted to the centre pivot irrigators which allows him to have 10 different irrigation programmes set up.

The farm has a variety of soils with different water-holding capacity and he has programmes that mean application rates can be varied across the length of the pivot.

“That means we can have an area getting 6-8mm in a pass while other areas (along the same length of the pivot) are receiving up to 12mm.”

Water can be switched off altogether as the pivot passes over laneways or troughs. Coupled with the use of soil moisture monitoring, the VRI technology means irrigation is much more precise, with just the right amount of water going on at the right time in the right place.

“It means we’re making best use of our water, growing more grass and there’s less potential for nitrogen loss so it’s more sustainable all round,” he says.

Another option under review is to replace sprinklers in the corners with subsurface drip irrigation, also as a way to improve water use efficiency.

Nitrogen use has dropped, with 189kg N/ha used last season.

This season, by early March Jonathon had used 138kgN/ha and expected total use for the year would be 175kg N/ha as an average across the farm.

“There will be some variability in rates from paddock to paddock but every paddock will be under the 190kg N/ha limit.”

This season, after completing the spring rotation plan, they held the first round to be slightly longer due to a slower spring.

“That saved a round of urea in itself,” he says.

Effluent is injected into the pivots, so it can be spread on up to 85% of the farm, making good use of its nutritive value.

The pivots are bucket tested to ensure they’re operating true to expectation which also ensures efficiency and sustainability.

Jonathon and Stacey say the next steps for them are to continue building their investment capital so they have options.

“It’s very much about working to maximise our investment whether that be in this farm or within the farming business group or some other opportunity.

“We want to own our own farm in the future and while we have plans for that you have to be flexible enough and be ready for opportunities.”

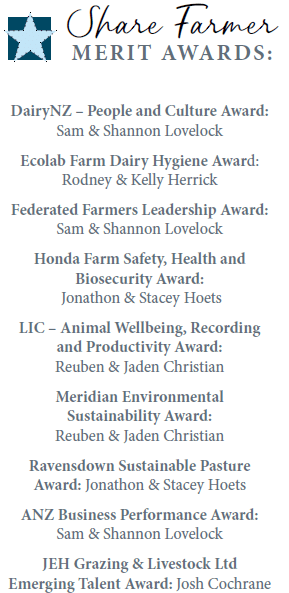

Runner up in the Share Farmers of the year Award for Canterbury/North Otago was Reuben and Jaden Christian and Sam and Shannon Lovelock placed third.