Progression through the system

A Hawke’s Bay couple have built an extensive dairy operation, planted thousands of trees and taken out the region’s top environmental award. By Jackie Harrigan.

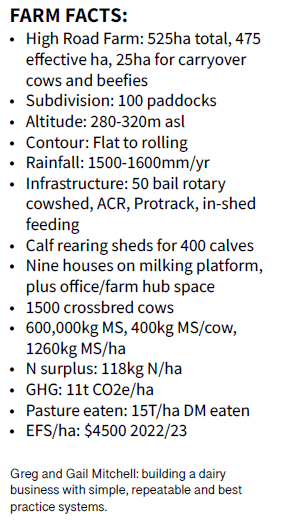

Greg and Gail Mitchell have been planting trees on their properties since their first 13-hectare Hamilton block, when they lived there 30 years ago and worked as a butcher and a nurse.

They have come a long way since, and their 1996 decision to go dairy farming meant they are now planting on a much larger scale with 10,000 to 12,000 native trees each year for the past four years, on their 525ha, 1500-cow dairy farm, and 900-cow, 345ha Kaweka dairy unit also at Patoka in Hawke’s Bay.

The couple have been driven to work, canny with their property purchases, but mainly, keen to learn everything they could about the industry and industrious in putting that learning into practice with simple, repeatable and best practice systems.

Their success in growing their business while focusing on good animal health, good soil health and good people management won them a handful of Ballance Farm Environment Awards for the East Coast region in 2023 including the Supreme award.

Judging came hard on the heels of the weather bomb of Cyclone Gabrielle – slamming them with up to 700mm of rain, damage to bridges, tracks and culverts and no road out of the district for a month, meaning no milk pickup and an immediate end to their milking season. Fortunately they, along with the other Patoka dairy farmers, were paid out for the season by Fonterra under a force majeure clause on a three-year production average, showing them “the value of belonging to a co-operative,” Greg says.

The couple, who have very complementary skills and similar attention to detail, have grown their business recently adding a 230ha runoff to make their system more self-sufficient and give them more scope for rearing beef animals. They have also invested in a beach house at Whangamata (for work/life balance) and a house in Napier as part of their succession planning.

Their growth in the dairy industry has been rapid. After one year as farm assistants they moved to a 25% lower order 170-cow job on the Central Plateau. The following year they moved to 50/50 sharemilking, (where they did the previous sharemilkers’ production by December 1). The following year they moved to a larger 500-cow job for the same owners and bettered the previous milker’s record by January 1. Two sons were also welcomed to the family in those sharemilking years. Five years after going dairying they were looking at a larger 50/50 job and their bank manager told them they could just go out and buy a farm. So they bought a 300-cow operation at Atiamuri and kept both the sharemilking jobs on, finding time to also tidy up the new farm – fencing waterways, planting trees, refencing and installing troughs and removing blackberry.

Three years later in 2004 they gave up the two sharemilking jobs and moved on to their Atiamuri farm, doing record production, before two years later in 2006, selling that farm, doubling their money, and trading up to a larger 450-cow operation.

“Each farm we have purchased and sold had been regrassed, we established good weed management plans, refenced and planted riparian areas as well as improved milk production, all from cashflow,” Greg says.

In 2008 they bought a Whangamata beach house and a 66ha runoff, in the midst of the GFC and a drought, and then in 2014 sold up in Atiamuri and bought a rundown 525ha, 1500-cow dairy farm in Patoka in a receivership sale, in the midst of another drought.

Two years later they bought another 346ha, Patoka 900-cow dairy platform, with just a dairy shed and added all the other infrastructure they needed.

In 2022 they bought a house in Westshore and in June 2023 took over a 230ha runoff in Patoka, making them self-sufficient for raising beef and grazing young stock.

They are most proud of the growth of their business, and the way that they have managed to scale up their farming system over 30 years from 12ha to 1100ha, growing to an operation producing around 1 million kg milksolids (MS).

Monitor and act, monitor and react is the mantra Greg and Gail use.

“Making decisive decisions and the timing of those decisions is key – every farmer does the same things and spends the same dollars, but it’s the planning and timing around the spending that counts, and how the spending is diluted by stock sales and milk income,” Greg says.

The Patoka farm was run down when they bought it from the receiver, milking 2500 cows in a high input system, importing $1 million worth of supplement and producing 600,000kg MS of milk out of a 50-bail rotary with one hour between morning and afternoon milkings, Greg says.

It had been converted from part of the original Hendley Station in 1996, but fencing was in straight lines, rather than following the contours of the rolling property.

As part of the development of the property, Gail and Greg have taken out sheep fences and changed fence lines, installed three races, reticulated water to two or more troughs in each paddock and fenced off many areas of gully and planted in natives.

“We have reinstated, fenced and planted out many of the station’s original stock water dams and now use them as silt traps, so that any overland flow will go through at least one and preferably two or three traps before reaching the Mangaone River, that borders 75% of the farm.”

The pair are active members of the Mangaone Catchment group, and say the greatest threat to water quality is P loss through sediment into the river as N loss is low. Before Cyclone Gabrielle smashed the river further down the catchment at Rissington, trout fishing and swimming were popular and trout numbers were high.

“We have noticed an increase in eels and freshwater crays in farm creeks and we are keen to talk to Fish and Game after winter about restocking the trout in the river.”

While in its infancy, Greg sees ways for the catchment group to work together on the ‘low hanging fruit’ – reticulating water systems, building sediment traps and fencing off and planting natives in areas across the upper and lower catchment.

With eight staff living on the farm, 50km from Napier, there was a need for more housing. The Mitchells have renovated and relocated 13 houses across the two Patoka properties – and kept a builder in full-time work for the past three years.

“All the homes are up to Healthy Homes standard, with heat pumps, double glazing, new kitchens and bathrooms, carpets and lino,” Gail says.

“We also converted an old woolshed into a farm office/hub with a big generator, BBQ area and accommodation.

“It’s a great place for meetings, parties and get-togethers which came into its own after the cyclone – all the team brought their freezers down to plug into the generator and we all reverted to village living, sharing cooking and resources.”

A major development project three years ago saw the Mitchells invest $650,000 into a new effluent management system, with two 50m weeping walls drying nutrient for cycling onto cropping areas and a 25 million litre effluent pond (based on 2100 cows) with bottom outlet to reduce sedimentation, that irrigates 125ha with very low application irrigators in the spring/ summer period.

Effluent waste is seen as a valuable resource not a compliance cost and individual paddock soil testing of the volcanic ash soils allows balancing of nutrient applied with reduced need for fertiliser application.

As a result of the individual paddock soil testing, four brews/mixes are formulated and applied across the farm, which Greg said is not easy to manage. A cropping programme of fodder beet crops (yielding 28T)are grazed in March/April /May to extend the grazing round while putting weight on the cows and milk in the vat, and then the ground is planted with oats as a cover crop to mop up the nitrogen.

Rolling paddocks are sprayed and drilled with chicory instead of turnips as a summer crop, reducing cultivation, and maize is now being grown on the platform to reduce cartage costs.

Future-proofing the platform is important to the couple who are planning to plant shade trees, and will cover the feedpad and capture the rain for use as washdown water at the cowshed or as irrigation.

They are looking at a second feed pad but the $3m cost of a herd shelter has been prohibitive.

They are watching the cost of solar coming down with a plan to install it at the cowshed to offset electricity costs.

Towards more efficient cows

Gail and Greg have been working towards more efficient cows for the past 30 years and their crossbred herd sits in the top 15% of cows for BW/PW (208 and 263 respectively). The 2022-born heifers are in the top 10%, Gail says.

“We moved to the crossbred cows for their better feed conversion efficiency and lower liveweight causing less pasture damage.

“They also emit less methane as they eat less than a big Friesian cow.”

Increasing per-cow production and pasture utilisation has seen them produce 600,000kg MS from 1500 cows on a platform that previously produced the same amount of milksolids from 2500 cows.

For the past 20 years they have not bred the bottom cows for replacement calves, preferring to mate them to beef breeds. They mate 200 cows with Speckle Park semen and supply a neighbour with the four-day-old calves. Charolais, Hereford and Belgian Blue cross calves are also bred to order and picked up at four days old.

While trying to eliminate bobbies, they say being in a movement control area for TB makes it hard to sell all of the calves and that Jersey bulls over the heifers produces a crossbred Jersey calf that is not in high demand.

“We have tried sexed semen but the hold rate is lower and costs are higher, so we now use daughter-proven semen and after starting calving on 20 July we can have 300 replacement heifer calves in the shed by 1 August,” Gail says.

Gail and her team rear 400 calves undercover in the calf sheds and 100-200 beef cross calves are reared alongside the replacement heifers. The rest are sold if possible to repeat buyers.

The first two weeks are full on with a second herd created after that time and the half way day this season was August 5.

The vet comes weekly for the first six weeks of calving, attending to any cows with retained cleanings, lame, sick or throwing a health alert – and disbudding calves at 3 weeks old with sedation, vaccination, DNA testing and applying EID. The calf then goes onto OAD feeding in the evening.

Under the full season twice-a-day (TAD) milking system, heifers and lighter cows are run in one milking herd, with two further milking herds, a colostrum herd and a penicillin herd.

Collars were added into the system in September 2021 and the Mitchells say they are great for identifying and auto-drafting any sick cows earlier than can be picked up by the team.

“We still use the same antibiotics but save dollars on a second dose as we can catch it early.”

The collars have relieved Greg from the cow shed for six weeks at mating and made it easier for staff.

“We are able to identify non-cycling cows easier and identify and treat sick cows earlier so they don’t become as sick. Any cows with distress alerts overnight are automatically drafted out for treatment.

“The collars were money well-spent because we are picking up cows before they actually get sick and picking non-cyclers at mating.”

The Mitchells herd test four times each year and also test for minerals in bloods, DNA test calves, BVD and Johnes test through milk alongside pregnancy testing through milk.

The farm adviser does formal cow body condition scoring four times each year as part of the farm philosophy of having healthy, well-fed cows.

Having quality stock has enabled them to earn nearly $1/kg MS in stock sales which is twice the dairy industry average.

A month out from mating they start to look at the collar data and create a fourth OAD herd of early calvers who have not yet cycled.

“We have managed to tighten up the calving and so get more days in milk from the cows although we haven’t really dropped our empty rate but we have managed to remove bulls from the farm.”

The empty rate of 10-12% is higher than their ideal of 8-9% (and way ahead of their Atiamuri rates of around 5%, when they were owner-operators.)

“It’s harder as you get bigger numbers and more staff – you need to get everything right pre-mating. A lot of people start to think of mating a month before but it really starts at the end of the previous lactation.”

Patoka is 50 minutes from town, and not the easiest to staff, but Greg and Gail have their own secret weapon for accessing staff on the High Road Dairies farm, Mika Kanae.

The Kiribati national has worked for the Mitchells for the past 11 years, taking on the contract milking role this season. Mika arrived in NZ as a school student on an academic scholarship and rather than go on to university, opted to go dairy farming with the Mitchells.

The couple have since employed and sponsored many of Mika’s relatives and friends from both Kiribati and Hastings, where there is a strong Kiribati community. There are currently six others from Kiribati on the farm and Greg and Gail say having a community of them and their families (26 on the farm) makes for a stable workforce, even if English is lacking.

During the cyclone aftermath when the farm was cut off for a month, and first supplies were helicoptered in thanks to Westpac bank, Gail says the farm reverted to village life – everyone shifted their freezers to the generator at the hub and shared meals and supported each other.

The lack of English, and often shyness in using their limited English, means the new workers start out feeding calves first under Gail’s tutelage.

“They master that quickly, using role modelling, gestures and translations and with some success comes confidence and they then move up to the cow shed and learn the procedures there,” she says.

“Their understanding of English is okay – it’s more shyness and not wanting to be seen to be wrong, so we keep it simple and have someone working alongside them until they know what they are doing.”

Short courses and onfarm training work best for the Kiribati workers and the team use a traffic light system for assessing skill levels and assigning training.

“We try to add skills every year.”

The Mitchells have tried many different rosters; 6-2, 7-2, 8-2, 8-3 but the staff prefer having every second weekend off so that they can get to town and church on the weekend.

“So we have gone back to 12/2 until the end of September and then 11/3 across the rest of the season. It was too hard on a 8/2, 8/3 roster because they only had every third Sat/Sun off and it was too long between weekends. This way we have the whole crew onfarm on Tues/Wed/Thursday which is good for continuity and meetings.

“They also work either an early or late shift and breakfast is supplied at the farm dairy for the start of the season.

“Staff retention is good with most team members staying three to five years and then many have gone on to other dairy farming careers,” Gail says.

The Kiribati enjoy working with their own people and while coming from a totally different culture where they have scarcely seen a cow or grass before, learning in a community and supported environment makes it easier for the immigrants. Helping Mika to take on the contract milking job has meant Greg has more time for the new runoff and Gail has kept on the role of running the calf rearing for the next three years to ease Mika into the overall responsibility.

Gail and Greg have two sons, one a pilot for Air NZ and the other a diesel mechanic, who are both involved in the family trust and different aspects of the farm.

Gail and Greg are keen to move off the farm to their house at Westshore, Napier in the next three years and have set up the contract milking agreement on the High Road Dairy and an equity partnership on Kaweka, the other Patoka farm, to make this possible.

Team Mitchell

- Eight full time staff, seven live on farm

- One fulltime tractor/ maintenance contractor lives off-farm

- 11 on 3 off roster in teams of four

- Either working early shift (4am-3pm) or late shift (7am-end of afternoon milking)

- Average 45-55 hours/week

- Salaries range $60k-$100k

- Bonuses: $100/month bonus for being grade-free, for less than 150k SCC, for keeping farm tidy / no rubbish, so $300 up for grabs each month

- Regular toolbox meetings at woolshed

- Breakfast for the team at cowshed during calving until end of calving

- Health and safety register.

Staff training:

- Training on the job works best, working one-on-one with senior staff

- Short courses (e.g. milk quality, chemicals)

- Staff prefer onfarm training as English is a second language

- Zoom calls have worked well

- Skills based on traffic light system Red = cannot do skill, Orange= learning skill, Green= can do skill and train others

- Skill set reviewed after annual staff reviews.

The Kiribati connection

The Republic of Kiribati is a group of 32 atolls spread over a vast area in the north Pacific (population around 120,000 on 22 populated islands).

Most of the atolls are barely more than six metres above sea level and surrounded by barrier reefs creating picturesque lagoons for fishing and water sports but making them top of the list for climate-change and coastal inundation through rising sea levels.

Just 75 Kiribati each year are welcomed to New Zealand through a ballot system whereby if they win the ballot, they can come to NZ, find employment and are guaranteed citizenship. There is a big Kiribati community in the Hawke’s Bay and Mika and one of the other team members have both been on the Kiribati community board based around the church and community.

Being prepared for a disaster:

- Lessons learnt from Cyclone Gabrielle:

- Storing enough generator/fuel for shed and house. (Including gas for BBQ, be aware helicopters can not carry 9kg gas bottles)

- Communication – Starlink satellite. Radios were knocked out by repeater stations losing power. Handheld walkie/talkies work well but need the ability to charge them

- Know your people – all people onfarm, not just staff.

- Know your community plan – who are the emergency contacts.

Key messages:

Be prepared to ask for help

Plan to be self-sufficient for a week

FOCUS on what you have got, not what you have LOST.