Smaller footprint, lower costs

The sky won’t fall if the dairy industry reduces its inputs and changes management practices to meet looming environmental regulations, nor will that spell the end of the New Zealand dairy industry. That’s the view of a former DairyNZ scientist. Words Elaine Fisher

Dave Clark outlined the opportunities and challenges of deintensification through reduced feed inputs and stocking rates at a SMASH field day at Pukehina in the Bay of Plenty late last year. Throughout his long career, Dave has advocated for the dairy industry to take the environment into account as part of management practices. “However, a lot of people think we can expand production and at the same time decrease our environmental footprint, but unfortunately biology does not work like that.”

What does work is deintensification, and for many farmers, doing so would actually save money.

“Transition towards deintensification gives an opportunity to reduce unprofitable feed inputs because, as shown in the Neal & Roche (2019) report; ‘on average, for every $1 spent on imported feed, total costs increased by $1.66 for the Waikato’ (based on 12 year’s DairyBase data),” Dave says.

“An argument against transition is that there is less opportunity to take advantage of higher milk prices and/or lower feed inputs costs. However, Neal & Roche (2019) found that from 2005-06 to 2016-17 there were only three years when the milk price was above $7.50 per kg MS and DairyBase farms were able to generate higher profit from using more imported feed.”

High stocking rates and the use of nitrogen fertiliser to boost pasture production alongside supplements such as PKE, maize silage, fodder beet, and in the South Island, cereal crops, is a relatively new practice in New Zealand dairy farming, he says.

“When I began working at Ruakura (Dairying Research Corporation) in 1992, not many farmers were using nitrogen because it was more expensive than now, relative to the milk price. Up until the 1990s most milk produced was from N- fixing white clover pastures, so it is only in the past 20 to 25 years that the industry has come to rely on synthetic nitrogen fertiliser to grow pasture.”

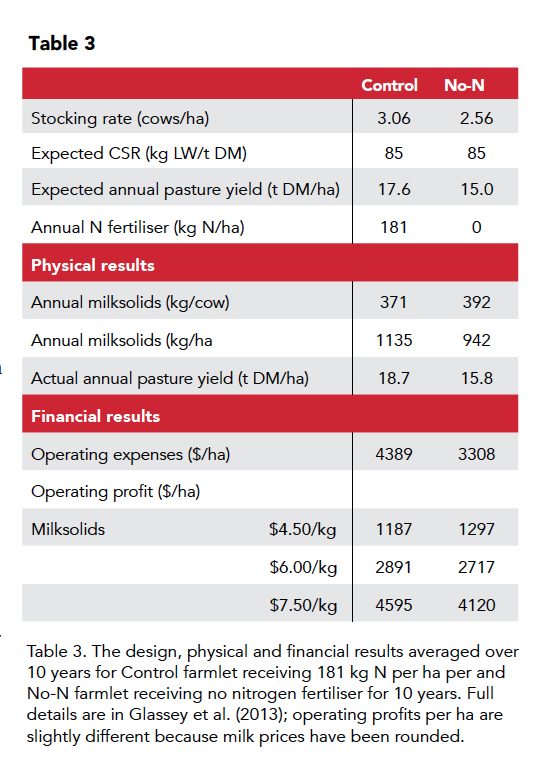

It is possible to return to a low or no-nitrogen system and still be profitable, as demonstrated by a nine-year experiment at the DairyNZ Scott Farm, Newstead.

At milk prices below $5.10/kg MS the No-N farmlet option was more profitable than the Control, but above this figure use of N fertiliser became profitable. But at $6.00/kg MS, operating profit decreased by only $174 per ha.

In the experiment, two farmlets, one receiving 181kg N/ha nitrogen (Control) and the other receiving no nitrogen (No-N) per year, were established on 1 June 2001 and continued until May 2011 (see Table 3).

Annual rainfall varied from 915mm to 1387mm; annual pasture DM yield from No-N farmlet varied from 12t DM/ha to 20t DM/ha.

“The range of climate conditions means that the results are a robust indicator of what can be expected if nitrogen fertiliser is completely removed from the farm system.”

The stocking rate of milking cows was reduced by 21.5% (total stocking rate was reduced by 16.3% if replacements on the No-N farmlet are counted).

This led to a 17% decrease in milksolids per ha and a 25% decrease in operating expenses per ha for the No-N farmlet.

“But of course, there is no need to reduce stocking rates by more than 20% and stop N fertiliser use altogether – there are plenty of intermediate options that might fit your farm much better,” says Dave.

The results from the DairyNZ farmlet stocking rate experiment have been used to justify the need for high stocking rates to optimise operating profit per ha. Following that experiment another was conducted at Ruakura No. 2 Dairy from 1999-2001.

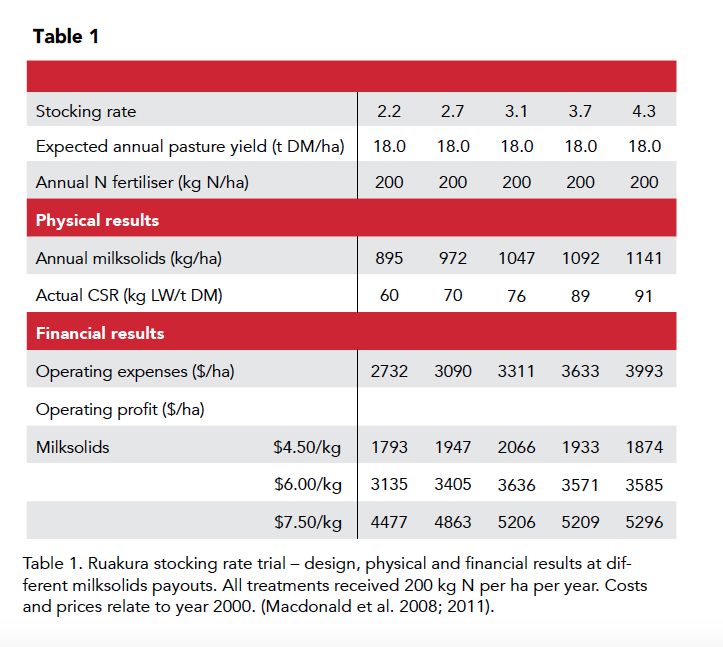

“This experiment concluded that financial performance was optimised at 3.3 cows per ha or a comparative stocking rate of about 77kg of live weight per t feed DM available. This conclusion held at milk prices from $4.30–$6.30/kg MS. Once milksolids price increased to $7.50/kg MS, stocking rates above 3.3 cows per ha became more profitable (Table 1).

“However, there’s a major issue – why use the same N rate (200kg N/ha) at all stocking rates?” asks Dave.

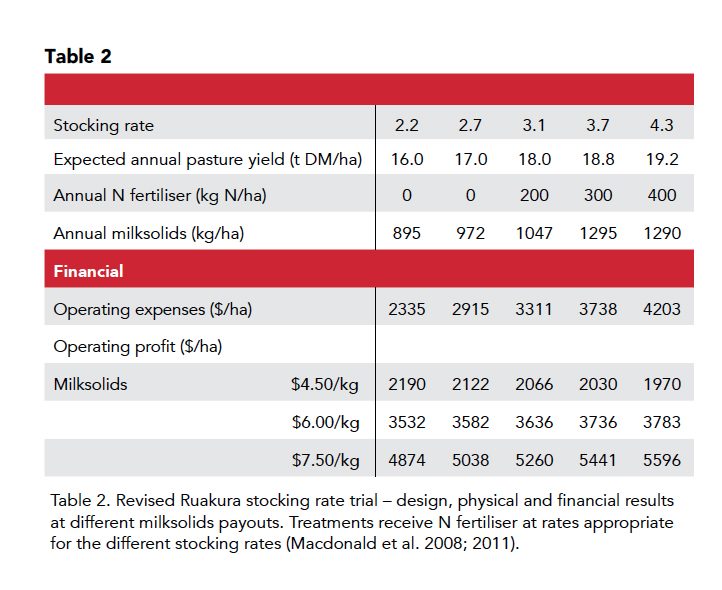

The experiment was ‘remodelled’ to answer the question – ‘What stocking rate optimises financial performance when a farmer is allowed to vary the input of the cheapest feed source?’

Nitrogen fertiliser was varied from zero at 2.2 cows per ha to 200kg N/ha at 3.1 cows per ha and 400kg N/ha at 4.3 cows per ha – based on the approximate amounts of pasture required at each stocking rate (see Table 2).

Then the expected changes in costs, milksolids yield and profit were calculated. The revised analysis shows that at less than $5.32/kg MS the stocking rate could decrease from 3.3 to 2.7 cows per ha without any decrease in profit per ha. Decreasing stocking rate by 13% from 3.1 to 2.7 cows per ha would lead to increasing profit by $56 per ha at $4.50 and decreasing profit by $54 and $168 per ha at milk prices of $6.00 and $7.50 respectively (Table 2). A 13% decrease in stocking rate (3.1-2.7) would not compromise profit greatly at $6.00/kg MS.

Dave says while deintensification may not suit all farming systems or farmers, there would be economic and environmental benefits for many others, particularly those in the lower quartile of the DairyNZ economic survey.

“Those in the top quartile are probably using irrigation or are farming on good soil types and have, based on the 2018-2019 figures, profits of up to $3000 per ha. If they deintensified by 10% they would still make a very good profit.

“They are unlikely to do so as they probably see themselves as efficient, and they probably are, and there are currently no real regulations on greenhouse gas emissions to force them to change.

“The real opportunity is for farmers in the lower quartile, making between $800 and $900 a hectare operating profit because they are probably using as much nitrogen and supplementary feed as some of the more profitable farmers but are not getting the same production.”

Dropping out some inputs and relying more on pasture would be economically more efficient but Dave says doing so requires higher pasture management skills to avoid problems with a surplus of feed.

“In recent times New Zealand has thought that the way to farm is to push stocking rates as hard as possible and fill the gaps with nitrogen fertiliser, PKE or maize silage. If we wind back stocking rates the fear is that we won’t be able to control pasture in spring. Making silage is expensive and if stocking rates are lower you need less silage anyway. Another factor is not being able to make use of high payouts when they come because of lower stocking rates and production. Those are realistic fears which can’t be underestimated.

“The point is there are a lot of average or low payout years before you get a high one. You can make lots of money from a high input system during high payout seasons, but high input systems carry financial risk and in low payout years can lose a great deal of money.”

Advocating for deintensification is to a degree against the current thinking, Dave admits. “There is no argument that in the past 20 years, the industry has gone through serious intensification and expansion. We increased our area under dairy, particularly in the South Island, and increased intensification. A lot of farmers 20 years ago would have been pleased with 300/kg MS per cow. Now many produce well over 400/kg MS per cow as a result of the use of supplements and nitrogen fertiliser.”

That increase has not come from New Zealand’s ryegrass pastures alone, he says. “Despite a lot of work to improve the production of ryegrass in the past 20 years, without the use of nitrogen, it does not deliver any more dry matter per hectare.”

Dave says New Zealand dairy farmers have about 10 years to reduce greenhouse gases by 10% and nitrogen leaching, and initially deintensification will help meet those 2030 goals.

“I try to be optimistic but believe that after 2030 we will need a combination of deintensification and new technologies to make the progress required to be carbon neutral by 2050. That seems a long time away but to develop and introduce those measures into farming will take all of that time.”

Since the 1970s when he worked at the Grasslands Division of the then DSIR (Department of Scientific and Industrial Research), Dave says New Zealand scientists have been working to develop efficient genetically modified ryegrass plants. “AgResearch has GM ryegrass plants in the USA but for technical and legislative reasons, no New Zealand dairy farmer is using GM ryegrass and I can’t see that happening within the next couple of decades.”

The same applies to vaccines to reduce the production of methane from cows. “It’s probably harder to develop an efficient methane vaccine than one for Covid-19, and miniscule amounts of money are being spent on its research.

“In the meantime, for every kilogram of pasture drymatter a cow consumes, it produces 20 grams of methane and we have nothing from technology at this stage that can drop that methane yield for grazing cows.”

Despite the challenges, Dave says dairy farming must focus on both its profitability and its environmental impacts.

“Farming is no longer about economics alone. It is about both the economy and the environment, and from that viewpoint deintensification looks a lot more feasible.”