Stepping up from across the ditch

Michael Smith - Southland/Otago Share Farmer of the Year. By Karen Trebilcock.

When Michael Smith’s parents Peter and Margaret needed one of their children to step up and take over the 187-hectare effective milking platform near Riverton in Southland, it was Michael and his wife Shahn who said yes.

Originally from Taranaki, they were living in Ipswich, near Brisbane. Shahn was a radiographer and Michael was with a construction company working as an environmental adviser carrying out their planning and environmental obligations. With his siblings still at high school, there was only him to take on the farm role.

“I was away from home a lot with the job in Queensland so we knew it was a lifestyle we couldn’t continue when we started a family,” Michael said. “We decided to give milking a go.”

A 10-month backpacking holiday around the world helped, but Shahn said it still took time to settle into the reality of the Southland farm and the region’s climate in 2016.

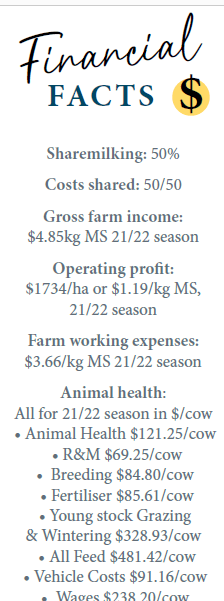

Michael spent a year with the contract milker, who happened to be a friend from school, learning the farm and then the couple took over fully, now 50:50 sharemilkers.

They were encouraged to enter the Dairy Industry Awards by last year’s Southland Otago sharefarmer winners Hamish and Emma Day.

“Emma told me ‘you guys need to enter this competition’,” Shahn said. “It will be so good for your business.

“But we really knew nothing about it. When we were filling in the entry form online we were wondering what we were getting ourselves into.”

What they had got themselves into was not only a competition but a series of meetings and events with sponsors and even team building with the other entrants.

“With Covid, it has taken a long time to reconnect with people, and this really helped. We got to meet so many people we knew about, but have never really talked to,” she said.

“It really made us also reflect on our business and set goals,” Michael said.

“I realised I needed to know what I was doing well, and what I could improve on. And how do we improve? How do we run a better business?

“The questions they asked us, it really made us think about what we were doing and why.”

They discussed writing a thank you speech the night before the awards in mid-March, “just in case we did win a merit or something,” Shahn said.

“Michael didn’t think we had any chance so he went to bed and I stayed up and did it.”

Just as well because they picked up three merit awards as well as the title.

“We know so many other people who need to enter, who are awesome at what they do, and this would help them so much,” Michael said.

They also plan to encourage all their staff to enter, either the manager or trainee competition.

Shahn works part time at Southland Hospital as well as looking after the administration work on the farm.

She juggles the shift work position, which is a 45-minute drive away, with child care at Riverton for four-year-old William.

“I don’t milk,” she admits.

“Yes, you do,” pipes up William.

“Well, sometimes. I help out during calving and doing odd jobs around the farm.”

They employ three staff across two farms and this season have taken on a casual milker as well. “That’s one thing we’ve learnt through the competition,” Michael said. “I’m spending too much time in the business, instead of on the business, if that makes sense.

“I’ll look out of the window and see a fence that needs fixing, and that is a tangible thing, you can fix it and it’s done and you feel good about it.

“But what I should be doing is focusing on budgets and cost structures and working out how to run this farm as efficiently as possible and those are long-burn things.

“There is not a lot of instant gratification with them.”

The farm works within the family business, with Michael’s sister now running a dairy farm and his brother looks after the drystock farm at Blackmount on the way to Lake Manapouri. One of Michael and Shahn’s aims is to increase the overall family business, possibly taking on another dairy farm in the near future.

While Shahn has a Bachelor of Applied Science majoring in medical imaging technology and a Diploma in Business majoring in leadership, Michael has a Bachelor of Science with a double major of ecology and zoology and a Postgraduate Diploma of Science in zoology.

He said he is always thinking about how to improve the land they are farming.

“There are always constraints, it has to make business sense, and we don’t own the land, but we’ve done a lot,” he said.

“We have 60ha in hill and we try to always look after that, putting the reel at the top of the slope so the cows walk uphill instead of down to get in and out of the paddock.

“Otherwise it can become a bit of a mudslide, especially as they always seem to like running downhill.

“Sediment retention ponds were installed, in conjunction with Environment Southland, the first year we were here, to slow down the water, retaining sediment and we have really seen the benefit of them.

“There is less scouring of the stream banks and less water in the paddocks after heavy rain, less overland flow.”

Instead of growing a summer brassica, they now plant a chicory, plantain and grass mix, grazing it in one-hectare blocks.

“It takes about two weeks to recover and then we can graze it again. At the end of summer it just goes back into pasture.

“It means we only have to cultivate it once if required per season and we gain increased feed over summer and fulfil our regrassing plan.

“Every year we are getting it better and better.”

Also “a work in progress” is their changing focus from milksolids production to profitability.

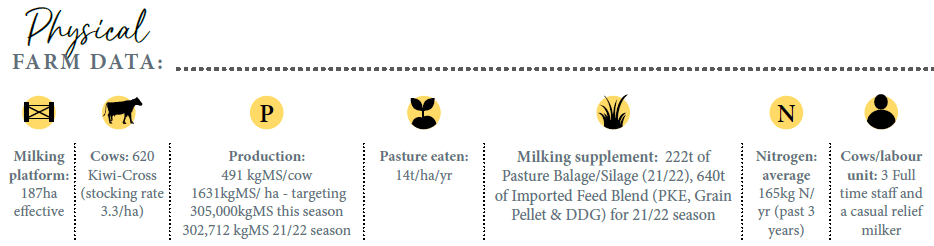

“We’ve got a fairly high stocking rate here, 3.3 cows/ha, but it’s only a milking platform. We don’t grow any crop here. Everything is off-farm for the winter. The young stock is also up at the grazing block.

“In the spring when the cows come back they go in the barn and are fed silage which we bring in from the other farms.”

There is also in-shed feeding of a grain mix.

“One of the things we want to do is have 50 to 100 tonnes of balage or silage, or a mix of both, on hand at all times.

“The extra costs of retaining extra feed doesn’t look good on the books, but it’s so we can always feed the cows well. We’re secure whatever happens with the weather.

“We’re really focusing on the cost of imported feed, getting that down, and making sure we can drip feed it into the budget, instead of buying it when we need it, when there is a feed pinch and everyone else is trying to buy it as well.

“We’re pretty good at pasture management but getting the right number of cows isn’t always easy.

“I got a bit carried away one year and we raised extra calves and they gave us 20,000 extra milksolids but it was too much for the farm.

“Plus that spring we had a really low death rate, I think we lost three cows all calving, so it compounded.

“This year it’s been the other way. The vets just say it happens that way sometimes.”

They’ve priced out every cow wearable but are still to make the jump.

“They all seem too expensive, we can’t justify it, but the staff are really keen to get collars.” Shahn said.

“We just haven’t decided. We’re more focused on growth but if it makes financial sense we’ll do it.”

They look after their team with dinners and outings such as ski trips during winter and jet ski or boating sports in summer.

“We operate an eight-days-on and two-off roster then eight-on and three-off, depending on the time of the year, and offer as much opportunity as possible for our team to enjoy the lifestyle of farming but to also pursue their own interests,” Shahn said.

“We really want to promote a good work/life balance.” As well, they make sure everyone in the team has equal opportunities to learn new skills and can work independently.

“It allows diversity and variety in day-to-day farming,” she said.