In eastern Southland, the Woolseys are sticking to DairyNZ’s mantra of grass only, low-cost dairying. Story and photos by Karen Trebilcock.

After 20 years of dairying I still don’t know what success looks like,” equity partner Dan Woolsey said at the mid-October Southland Pasture Summit in Southland.

After 20 years of dairying I still don’t know what success looks like,” equity partner Dan Woolsey said at the mid-October Southland Pasture Summit in Southland.

With his wife Emily, he milks 1250 cows at peak through two dairies at Gorge Road with seven full-time-equivalent staff in Eastern Southland only minutes’ drive from the southern coast. Running a system one operation, with fodder beet relied on to put condition on the cows in winter, the Woolsey’s farm aligns to major sponsor of the event DairyNZ’s mantra of grass only, low-cost dairying. The audience, which, apart from industry reps, was mostly young couples, obviously hungry for good pasture and progression knowledge.

Although the Woolsey’s five-year-average operating profit was now $3.08/kg milksolids (MS) and $3933/ha, Dan said their growth had never been in a straight line.

“We started out in our 20s when interest rates were 9%, the payout was three to four dollars and costs were low.

“Our friends were going on OEs but we stayed behind and managed to buy a farm instead.”

The farm was a sheep and beef property and they converted and sold it while they went through a series of positions including management, contract and lower order sharemilking in Southland.

Seven years ago they became equity partners on the Gorge Road farm with Dan’s parents who are fourth-generation dairy farmers looking after 484 hectares with 450ha effective and of that 30ha in fodder beet each year.

Milked through a herringbone is a 525-cow Jersey herd and 725 Kiwi Cross cows are milked in a rotary.

The 300 replacement calves once weaned are sent to a grazier and all cows are wintered off farm except for the R3s which are kept at home.

Cows are transitioned on to fodder beet before leaving for wintering and the R2s are first home on July 20 with planned start of calving August 1 with the rest of the herd following and calving 10 days later.

“We find looking after those R2s and R3s a little bit better helps with mating,” Dan said.

Heifers are kept separate from the rest of the herd until Christmas following calving, again to improve their mating chances.

Cows remain on a fodder beet and balage diet until going on to bark pads for calving where there are self-feed silage stacks. From calving it is grass-only.

Cows are milked once-a-day for three weeks following calving enabling all staff to “be home by 4.30” in the spring.

“Our aim is always to feed only grass once they are calved,” Dan said.

“If there are small deficits in feed we hold or increase round lengths, reduce the grass being fed and start once-a-day milking.

“We always have bunkers of silage as insurance and after that we buy in.

“The only reason we would feed supplements such as balage would be to hold condition scores, not to make milk.”

However, last year’s wet spring and dry summer and autumn challenged them and he admitted they used 100 tonnes of palm kernel. This spring they were 13% ahead on production so far and were feeding the cows 20kg drymatter (DM) of grass each day.

Culled cows began leaving the property in February and were all gone by the start of April enabling them to slow the round to build feed into the autumn with covers at 1900kg DM/ha at drying off.

No mating interventions are done with bull of the day used either Jersey for the Jersey herd or Kiwi Cross with the other. The aim is 300 replacements.

“It takes five straws to get a heifer calf so that’s 1500 inseminations which takes us usually between five to five and a half weeks and then we stop.”

Jersey bulls are used afterwards with mating for 10 weeks.

“Our goal is a mid-sized animal which holds its body condition and has good feet. Our Jerseys are about 440kg and our crossbreds about 460kg.

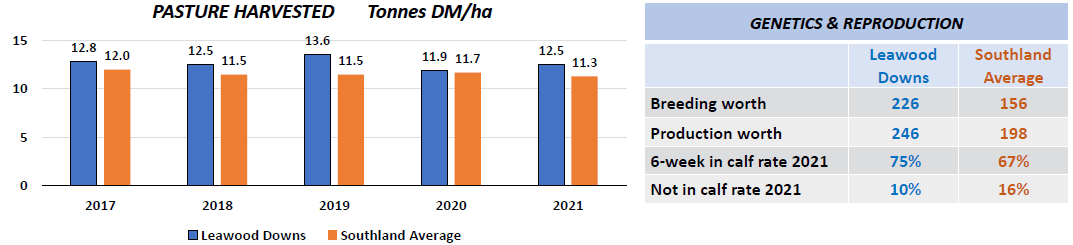

Production is 440kg MS/cow and 1310kg MS/ha with BWs at 226. Empties for last year were 10%.

Dan said while he was not interested in what went in the vat, he did spend time on pasture harvested which last year was 12.5T DM/ha.

“This is not A-class land. We do a lot of work to make sure we can harvest the feed it grows.

“Our golden rule is we never go faster than a 22-day round and we 24-hour-graze so no temporary fences.

“We use the mower as a tool pre-grazing to make sure there is quality grass for the next round. The mower is on the tractor all season. “Nitrogen goes on little and often behind the cows throughout the year. If it gets too wet we have our own gear to put it on, otherwise it’s the bulky.

“Last year we put on 184kg N/ha. We would have put on more but there wasn’t the rain. We’re always looking for that rain window.”

Fertiliser prices were a concern this year and he expected they would be mining some of the phosphate they had built up on the property during the past few years.

“Our Ps are up at 33 so we can do it. I’ve always put 10% more fertiliser on than suggested which is why we can do it now.”

They had soil-tested every paddock and would be targeting those in need.

Almost all of the farm could be reached by the effluent system and each year different sections were targeted as weather allowed.

Their goal of maximising profits from pasture to reduce debt and improve infrastructure had begun with a focus on “needs not wants”, Dan said.

“We’ve never done hire purchase, we only borrow money to make money and we focus on our core business.

“It’s about committing rather than just getting involved.”

He said surrounding themselves with positive people, being open to opportunities, never being afraid to learn and exercising patience had also been important.

“But we still want to have a life. This is a career for our entire lives.

“We are doing this for the long term so our model is to keep things simple, to enjoy it and make sure our staff enjoy it too.”