Ted and Sue Rollinson have improved productivity on their farm and it’s also lightened their environmental footprint. Sharemilkers Tom and Leanne Heneghan share the couple’s passion for water and pasture management. Anne Lee reports.

There have been big changes on Ted and Sue Rollinson’s Dorie dairy farm over the past six years, with no shortage of investment or effort from the couple and their 50-50 sharemilkers Tom and Leanne Heneghan.

Improving productivity and lightening the farm’s footprint have been among the drivers for what has essentially been a reconversion of the 380ha, 1500-cow farm with reductions in nitrogen loss and more efficient water use the key environmental outcomes.

As it turns out that also helps create greater efficiencies in terms of greenhouse gas (GHG) emissions.

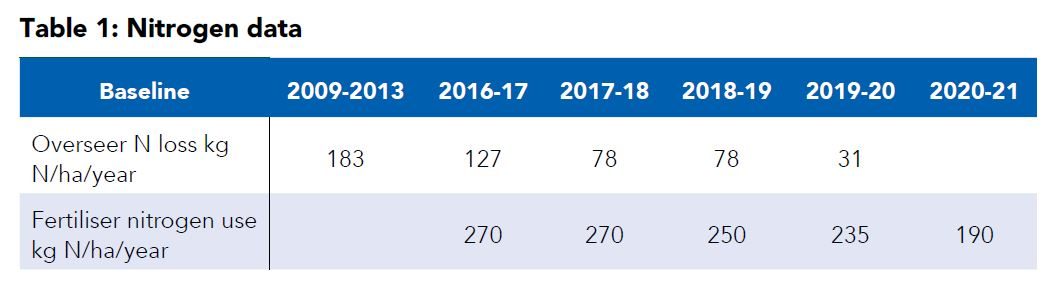

Nitrogen (N) loss as measured by Overseer has dropped by a massive 83% on their baseline N loss figure and now sits at 31kg N/ha/year, (see table one).

The baseline figure in Canterbury is the average annual N loss over the 2009- 2013 period. Better irrigation efficiency also means better use is made of the precious river-based water resource that feeds the farm.

With climate change predicted to bring greater weather variability, making the best use of water and improving reliability has to be a priority.

Efforts at the farm have been recognised, with Ted and Sue named as the New Zealand region winners of the inaugural Zimmatic Sustainable Irrigation Awards.

Ted and Sue originally converted the farm in 1981, making it one of the earliest in a wave of conversions that continued over the next 20 years.

Irrigation back then was border-dyke, with water brought to the top end of paddocks via races and released through gates to flood down the slope of the paddock to the other end.

As the understanding of water use efficiencies grew, they made changes by widening the distance between borders and laser levelling paddocks to improve infiltration rates.

They had used Rotorainers on support land and could see the benefits in pasture production from spray irrigation, so in 2014 embarked on a major redesign. It meant six new pivots and 10 sets of K-lines, with some tree lines removed, new lanes put in, and re-fencing of pretty much the whole farm.

Needless to say, it took several seasons of Tom doing all the fencing and Ted spending hundreds of hours on the tractor, grader and digger.

“It was a massive job – the only contractors we used were to build the irrigation pond and fence it and build the pivots – everything else has been done in-house,” Tom says.

Tom and Leanne have been with the Rollinsons for 12 seasons and to say they live and breathe water and pasture management, just as Ted has over the years, is an understatement.

“I have three weather apps on my phone and we use a weather station down the road to get ET (evapotranspiration) rates.

“We’ve got moisture probes too and – these things called eyes – they’re very important,” he says wryly.

“We know the spots on the farm that are first to show signs of moisture stress and likewise any signs of overwatering.

“What the moisture probes have shown us is that what we were doing – driving around the farm and observing, using a shovel to check what’s happening in the soil – those methods were correct.”

All Canterbury dairy farms have farm environment plans that must be audited by regional council approved independent auditors.

“To get an A grade we have to have probes and show we’re actively managing irrigation to do everything we can to stop the soil getting too full and creating drainage down through the soil profile.”

They’ve been audited twice since the rules were brought in and each time received an A grade.

The probes automatically telemeter soil moisture data that’s then available via both phone and computer and presented graphically so Tom can see at a glance where it’s sitting relative to stress point and capacity.

The pivots can be turned on and off with the flick of a switch and variable rate irrigation (VRI) is fitted to three of the six pivots, allowing different areas within the same pass of the pivot to receive different rates of water.

“We’ve had the VRI in for three years and every year we’re tweaking the main plan,” says Tom.

“We have it set to apply different rates according to soil type but I can change the rates on my phone as well as the computer, so it’s very easy to adjust rates when we see a specific area where there’s moisture stress or too much water going on.

“You can be a lot more precise and almost instantly react if you need to.”

They have different plans according to the time of year too, with spring and autumn rates typically about 10mm, lifting to 15 and even 20mm in the peak of summer.

While VRI is great technology it’s not without its hassles and the constant collapse and opening of the soft pipe between the valve and sprinkler head as the valve opens and closes has caused some pipes to split and leak.

“The irrigation company has a solution so hopefully we’re on top of that one now.”

Bucket tests are carried out regularly for compliance, but also as needed if Tom suspects there’s an issue.

The K-lines are shifted twice a day to improve efficiency and Tom says because they’re spread around the farm in areas where the corner arms don’t reach, there’s every opportunity to be using those all-important eyes to check pasture and the irrigators.

“You catch yourself doing it automatically – looking at the tyres, the fence deflectors, the nozzles – making sure there’s a nice even spray.”

The farm is part of a small irrigation scheme, the South Rakaia Irrigation Partnership, which Ted was instrumental in establishing. Tom and three neighbours, also on the scheme, intensively manage the water take from the Rakaia River.

The take is based on river flows with restrictions coming in as river levels drop – although they can also access stored water from Lake Coleridge through an arrangement with Trust Power.

“We’re not only watching the weather here, we’re also watching what’s happening in the headwaters because that has a direct impact on the river flows down here.

“I’m watching rainfall at Arthurs Pass and Carrington and flow rates in the river – all on my phone – because we know if there’s heavy rain up there, within 12 to 24 hours the river level will rise and we’ll have to go down and pull plates where it’s diverted out of the river to the scheme so we don’t get inundated along here.

“When we see water levels dropping and the forecast looks like that’s going to continue, we’re making sure our pond is full and that we’ve irrigated to get soil moisture levels closer to the upper limit.”

The improved water use efficiency, slightly increased effective area due to the removal of border-dyke headraces, and some tree lanes and pasture renewal as borders have been removed have all helped to noticeably increase annual pasture production. The intensity of Tom’s water management is equalled by his management of pastures, with farm walks carried out weekly, pre-grazing covers and post-grazing residuals checked, and pasture allocations all meticulously monitored and measured.

“The best year we had under border-dyke irrigation we grew 19t drymatter (DM)/ha, and based on the plate meter readings the best year we’ve had under pivot was last season at 22tDM/ha.”

Regrassing has been carried out as borders have been removed and now that’s completed, Tom says pasture renewal will be based on regrassing the worst performers.

They’ve been using a mix of tetraploid and diploid ryegrasses with Trojan (diploid), Viscount (tetraploid), One50 (diploid), and most recently Base (tetraploid) and Platform (diploid) the preferred cultivars.

“We’ve been able to go into much higher covers and still achieve residuals with these new grasses.”

That’s enabled them to push round length out slightly. The ability to capitalise on the ability of the newer varieties to grow big tonnages could be limited by the recent cap on nitrogen.

“Normally at this time of year we’re starting to push a bit of feed ahead of us so we’re not reliant on supplement through autumn, but I’m not sure if it’s a seasonal thing or we’re already seeing an effect of lower nitrogen inputs because we’re struggling to get that wedge,” he says.

This season their fertiliser plan has them targeting 190kg N/ha with ammonium sulphate used in spring and autumn and coated urea used in between, which helps cut losses of the potent greenhouse gas nitrous oxide losses. They’re now starting applications later than normal in spring despite their planned start of calving being earlier than many at 23 July for cows and 15 July for heifers.

“The ammo rate has remained the same at 40kg N/ha but we’ve dropped the urea rates back to 25kg N and it’s put on as N-Protect.”

With the pressure on nitrogen use Ted has been working on lifting clover content. One of the first steps has been to ensure fertility is right for good clover establishment and growth.

Potassium and molybdenum levels are important. Clover needs light and is easily shaded out by high yielding ryegrasses, so after plenty of research Ted and Tom are trialling broadcasting clover seed inoculated with rhizobia.

They’ve chosen upright varieties they hope will be better able to compete.

“The idea is we’ll broadcast it about 10 days before the cows go into it, let it settle, irrigate it, and then the cows will trample it in.”

Tom says they feel they’re making good inroads with what they’ve done to minimise nitrogen loss but are feeling a little uncertain about what’s in store with cutting carbon and methane emissions.

They’re already low input in terms of bought-in feed, with 250kg/cow of palm kernel used last season along with just 50kg DM/cow of silage imported from the support block.

“When you look at the options they’re talking about we don’t have a lot of levers left to pull from here on unless there’s some scientific breakthrough,” he says.

But the key is to be prepared and not bury your head in the sand so you have time to understand and prepare, he says.

Ted works with Charlotte Glass from AgriMagic to identify and manage both water and nutrient issues and now has carbon emissions on the watchlist.

“Ted’s always looking at what’s coming over the horizon and it’s something we talk about.

“You’ve just got to keep informed, things have been changing rapidly and that doesn’t look like stopping any time soon.”